TM 55-2815-574-24

0095

ASSEMBLY - Continued

CAUTION

Driven gear must be centered on driven shaft to give proper end clearance and

chamfered end of gear teeth of the production gear, must face fuel pump body. Failure

to comply may result in damage to equipment.

NOTE

If a service replacement gear with a slot is used, slot must face toward fuel pump

cover.

a.

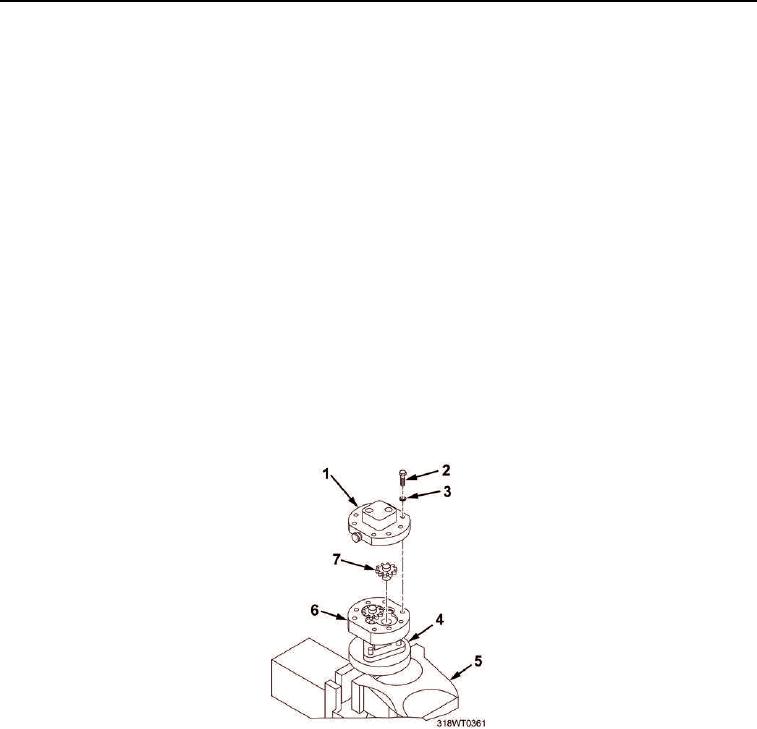

Use lubricating oil to lubricate gear assembly (Figure 13, Item 7).

b.

Install gear in pump body (Figure 13, Item 6).

10.

Install fuel pump cover (Figure 13, Item 1) on fuel pump body (Figure 13, Item 6).

a.

Apply a thin coat of adhesive sealant on face of fuel pump cover (Figure 13, Item 1) outside of gear

pocket area.

b.

Align fuel pump cover (Figure 13, Item 1) with two dowel pins on fuel pump body (Figure 13, Item 6).

c.

Install fuel pump cover (Figure 13, Item 1) on fuel pump body (Figure 13, Item 6).

d.

Install eight bolts (Figure 13, Item 2) and lock washers (Figure 13, Item 3) to secure fuel pump cover

(Figure 13, Item 1) to fuel pump body (Figure 13, Item 6). Tighten bolts alternately and evenly.

Figure 13. Gear Assembly Installation.

CAUTION

Do not coat first two threads of fittings with sealing compound. Failure to comply may result

in damage to equipment.

11.

Avoiding first two threads, apply a thin coat of non-hardening sealant to threads of inlet port

(Figure 14, Item 2) and outlet port (Figure 14, Item 3) elbows.

12.

Install inlet port (Figure 14, Item 2) and outlet port (Figure 14, Item 3) elbows onto the replacement fuel

pump (Figure 14, Item 1).