TM 55-2815-574-24

SUSTAINMENT MAINTENANCE

ENGINE

LUBE OIL SYSTEM CRANKCASE PRESSURE TESTING

INITIAL SETUP:

Tools and Special Tools

References

General mechanic's tool kit

FM 4-01.502

(WP 0179, Table 1, Item 130)

TM 55-1925-205-10

Chemical gloves (WP 0179, Table 1, Item 52)

Industrial goggles (WP 0179, Table 1, Item 54)

Equipment Condition

Vertical tube manometer

Propulsion module ventilated

(WP 0179, Table 1, Item 82)

(TM 55-1925-205-23)

Personnel Required

Engineer 88L

TESTING

WARNING

Remove all jewelry before conducting maintenance. Do not wear watches, rings,

identification tags, or other jewelry which could short across electrical components or catch

on vehicle components. Failure to comply may result in personnel injury or death.

NOTE

This task is typical for both the port and starboard engines.

1.

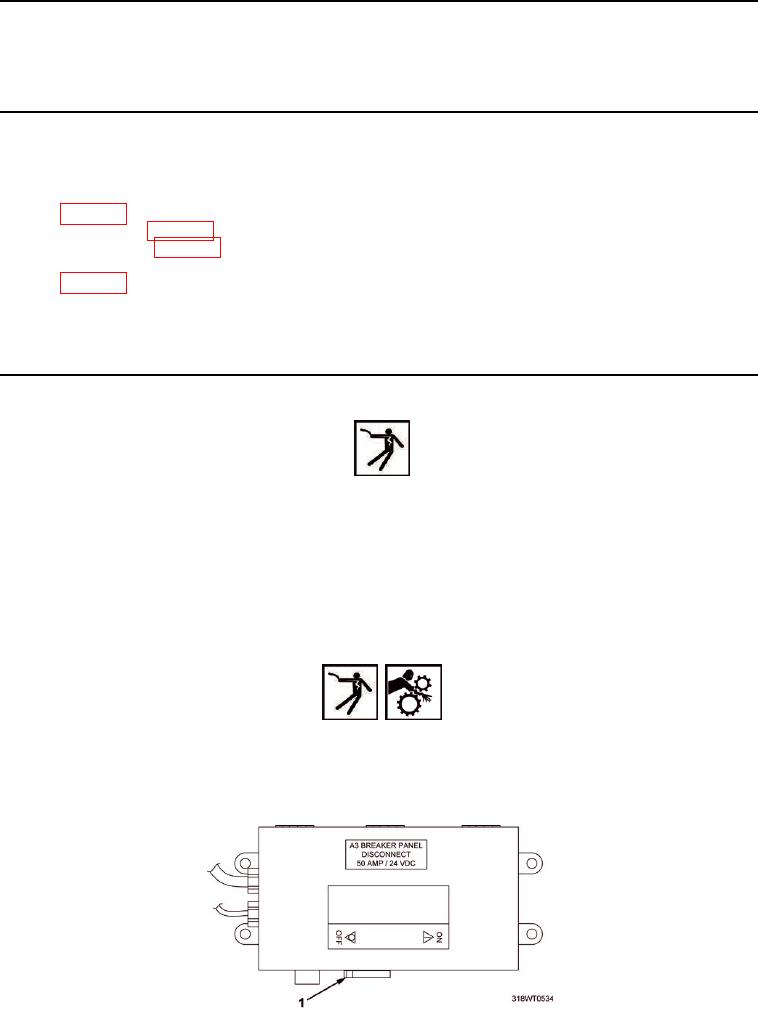

Place A3 breaker switch (Figure 1, Item 1), located on A10 panel, in OFF position. Refer to

TM 55-1925-205-10 for breaker location.

WARNING

Before attempting any maintenance, ensure power supply (switches, circuit breakers, etc.)

has been disconnected and locked/tagged out against unauthorized accidental start-up or

else death or serious injury due to electric shock and/or moving machinery could occur.

2.

Lock Out/Tag Out (LO/TO) A3 breaker switch (Figure 1, Item 1). Refer to FM 4-01.502 for LO/TO procedure.

Figure 1. A3 Breaker Switch.