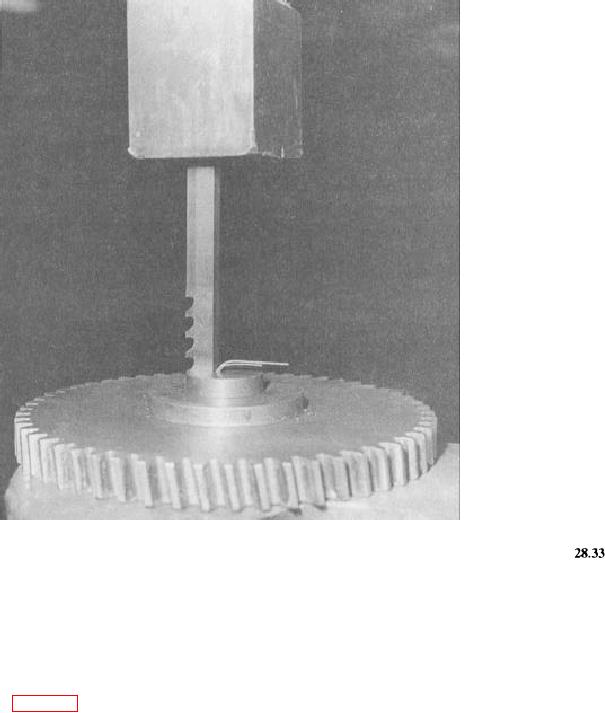

Figure 2-38.--Broaching a keyway on a gear.

keyway broach requires a bushing that will fit snugly

around the hole to be broached is perpendicular on

both the entry and exit sides.

in the hole of the part and has a rectangular slot in it to

slide the broach through. Shims of different

You will need a considerable amount of pressure

thicknesses are placed behind the broach to adjust the

to broach, so be sure the setup is rigid and all safety

precautions are strictly observed. Use a slow, even

pressure to push the broach through the part. That

A broach is a relatively expensive cutting tool and

will produce the most accurate and most safe results

is easily rendered useless if it is not used and handled

with the least damage to the broach. Do not bring the

properly. Like all other cutting tools, store it so no

broach back up through the hole, push it on through

and catch it with a soft cushion of some type. Use a

cutting edge is in contact with any object that could

lubricant to broach most metals. They help to cool the

chip or dull it. Preparation of the part to be broached

tool, wash away chips, and prevent particles from

is as important as the broaching operation itself.

galling or sticking to the teeth.

Make the size of the hole so the beginning pilot

section enters freely but does not allow the broach to

fall freely past the first cutting edge or tooth. If the

SCREW THREAD INSERTS

hole to be broached has flat sides opposite each other,

you need only to measure across them and allow for

A screw thread insert (called inserts for the

some error from drilling. The broach will sometimes

remainder of this section) is a helically wound coil

have the drill size printed on it. Be sure the area

designed to screw into an internally threaded hole and

2-20