receive a standard-sized externally threaded fastener

hole when the threads have been corroded or stripped

away. It also increases thread strength when the base

metal of the part is aluminum, zinc, or other soft

materials. Before using inserts for a repair job,

carefully evaluate the feasibility of using this method.

When you have no specific guidance, ask your

supervisor and refer to your Type Commander

Quality Assurance Manual.

Inserts come in sizes up to 1 1/2-inch in diameter

in both American National and Unified, and both

coarse and fine thread series. The overall length of an

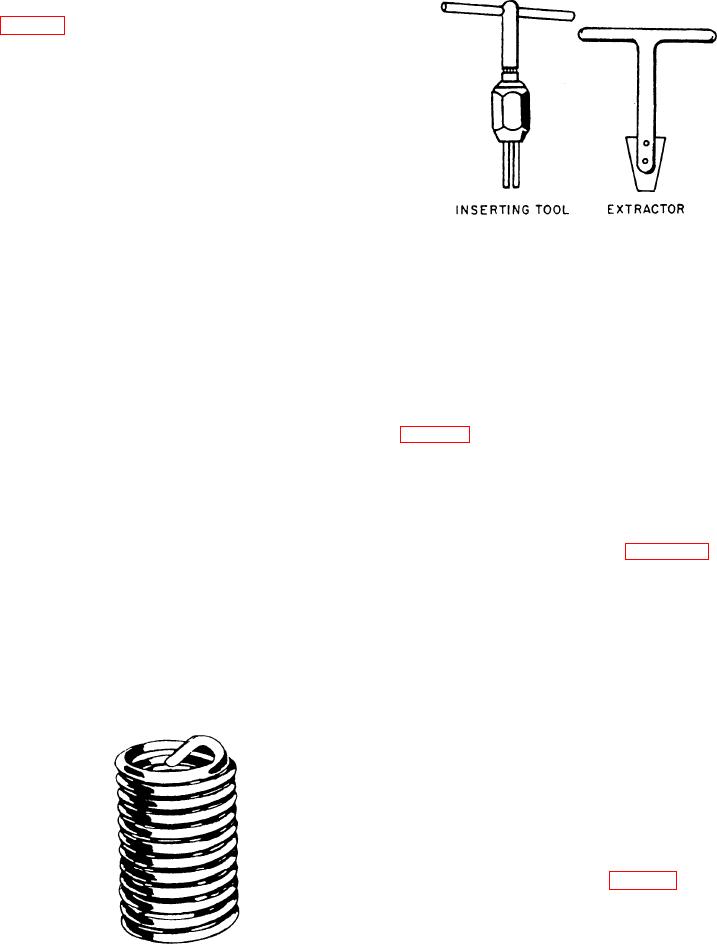

Figure 2-40.--Screw thread insert tools.

insert is based on a fractional multiple of its major

diameter. A 1/2-inch insert is available in lengths of

1/2 inch, 3/4 inch, 1 inch, and so on. Inserts are

require a 1/2-inch distance from the center of the hole

normally made from stainless steel. However,

to the nearest edge of the part. The tap drill size for

phosphor bronze and nickel alloy inserts are available

each of the taps is marked on the shank of the tap.

The diameter of this drill will sometimes vary

by special order.

according to the material being tapped.

Several tools are used to install and remove

The next tool you will use is an inserting tool

inserts. They are essential if the job is to be done

correctly. The most important tool is the tap used to

specific range of insert sizes. Within each of these

thread the hole that the insert will be screwed into.

styles are tools for each size of insert. All of the

These taps are oversized by specific amounts

inserting tools have similar operating characteristics.

according to the size of the insert. The oversize tap

Either slip the insert over or screw it onto the shank of

should provide a class 2B or 3B when the insert is

the tool until the tang (the horizontal strip of metal

installed. As an example of the amount of oversize

involved, a tap required for a 1/2 - 13 UNC insert has

engages the shoulder or recess on the end of the tool.

a maximum major diameter of 0.604 inch. Because of

Then, install the insert by turning the tool until the

the increase in the size of the hole required, be sure

correct depth is reached. Remove the tool by

there is enough material around the hole on the part to

reversing the direction of rotation.

provide strength. A rule of thumb is that the minimum

amount of material around the hole should equal the

After you have the insert properly installed, break

thread size of the insert, measured from the center of

the hole. Using this rule, a 1/2 - 13 UNC insert will

fastener that will be screwed into the hole. A tang

break-off tool is available for all insert sizes of

1/2 inch and below. The tang has a slight notch

ground into it that will give way and break when

struck with the force of the punch-type, tang break-off

tool. On insert sizes more than 1/2 inch, use a

long-nosed pair of pliers to move the tang back and

forth until it breaks off.

When you must remove a previously installed

several different sized tools that cover a given range

of insert sizes; be sure you select the right one. Insert

the tool into the hole so the blade contacts the top coil

of the insert approximately 90 from the beginning of

the insert coil. Then, lightly hit the tool to cause the

Figure 2-39.--Screw thread insert.

blade to cut into the coil. Turn the tool counter-

clockwise until the insert is clear.

2-21