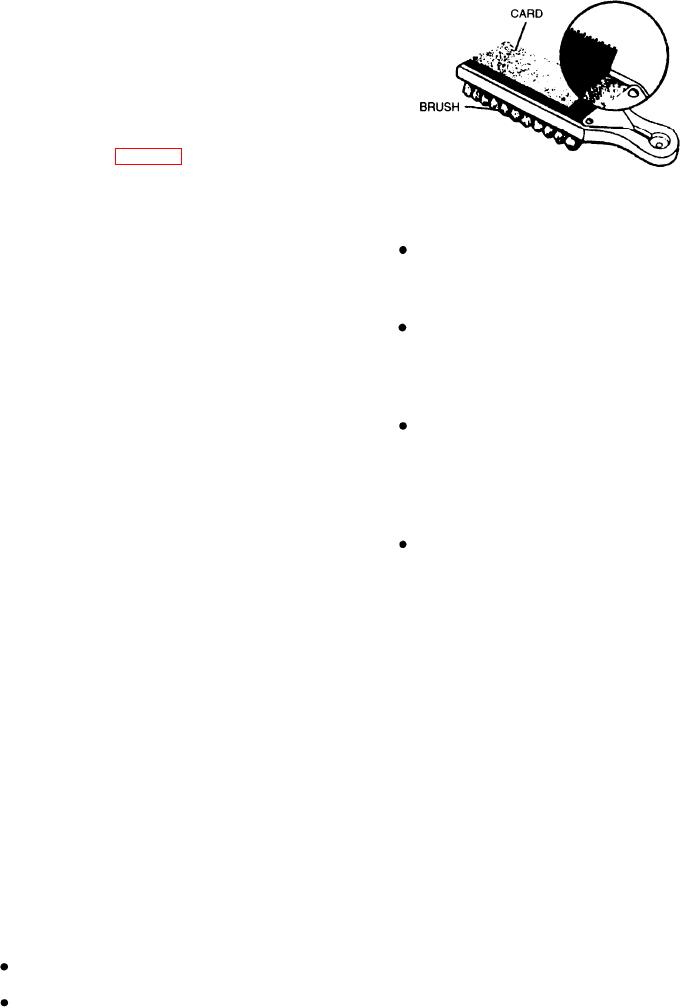

USING THE FILE CARD AND BRUSH

As you file, the teeth of the file may become

clogged with metal filings and scratch your work.

This is known as PINNING. You can prevent pinning

by keeping the file teeth clean. Rubbing chalk

between the teeth will help prevent pinning, but the

best method is to clean the file often with a file card

and brush. This tool (fig. 2-37) has fine wire bristles

on one side and a stiff brush on the other side. Use the

Figure 2-37.--File card with brush.

file card with a pulling motion, holding it parallel to

the rows of teeth. Then, use the brush to remove any

loose filings.

Place the ram in contact with the work by hand,

so the work is positioned accurately in alignment with

HYDRAULIC AND ARBOR PRESSES

the ram.

Use a piece of brass or other material (slightly

Hydraulic and arbor presses are used in many

softer than the workpiece) between the face of the ram

Navy machine shops. They are used to force

broaches through parts, assemble and disassemble

and the work to prevent mutilation of the surface of

equipment with force-fitted parts, and many other

the workpiece.

shop projects.

Watch the pressure gauge when you use a

Arbor presses are usually bench mounted with a

hydraulic press. You cannot determine the pressure

gear and rack arrangement. Use them for light

exerted by "feel." If you begin to apply excessive

pressing jobs, such as to press arbors or mandrels into

pressure, release the pressure and double check the

a part or to force a small broach through a part.

work to find the cause.

Hydraulic presses can be either vertical or

When pressing parts together, if possible, use

horizonial, although the vertical design is probably

a lubricant between the mating parts to prevent

more common and versatile. A hydraulic press can

seizing.

generate pressure ranging from about 10 to 100 tons

in most Navy machine shops. The pressure can be

Most handbooks for machinists have information

exerted by either a manually operated pump or an

concerning the pressure required to force fit two

electrohydraulic pump.

mating parts together. The distance the parts must be

pressed directly affects the required pressure, and

Regardless of the type of press equipment you

use, be sure to operate it correctly. The only way you

pressure. As a guideline you can use to force-fit a

can determine the amount of pressure a hydraulic

cylindrical shaft, the maximum pressure, in tons,

press exerts is by watching the pressure gauge. A part

should not exceed 7 to 10 times the shaft's diameter in

being pressed can reach the breaking point without

inches.

any visible indication that too much pressure is being

applied. When using the press, you must consider the

As an example of operating a press, we'll explain

how to broach a keyway. Broaching is a machining

corrosion and marred edges; and overlooked

process that cuts or shears the material by forcing a

fastening devices, such as pins, setscrews, and

broach through the part in a single stroke. A broach is

retainer rings.

a tapered, hardened bar, into which teeth have been

cut. The teeth are small at the beginning of the tool

Observe the following safety precautions when

and get progressively larger toward the end of the

you use presses:

tool. The last several teeth will usually be the correct

size of the desired shape. Broaches are available to

Always wear safety glasses and a face shield.

cut round, square, triangular, and hexagonal holes as

well as internal splines and gears and keyways. A

Make sure the work is adequately supported.

2-19