is not cut, you will have difficulty forming the side of

thumbscrew. Then scribe the arc or circle in the same

the box. When you have the drip pan, or box, laid out,

manner as with the dividers.

form the pan by breaking (bending) the side up 90

degrees. If you have made all of your measurements

MAKING SIMPLE LAYOUTS

accurately, and have made your breaks on the line, the

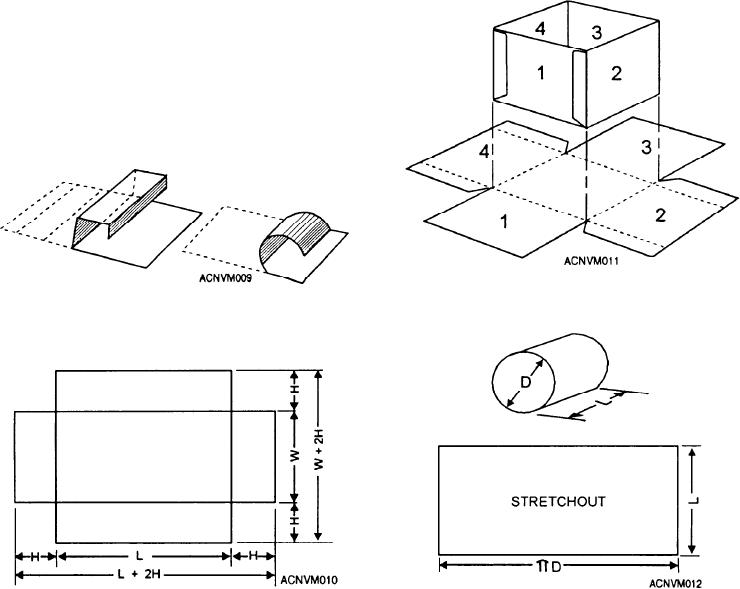

A STRETCHOUT is a pattern on a flat sheet that

upper edge will be even all around, like the one shown

has not been formed into a three-dimensional object.

in figure 12-11.

Figure 12-9 shows three-dimensional objects being

The STRETCHOUT OF A CYLINDRICAL JOB

formed from flat patterns. When jobs are laid out, you

will be rectangular in shape, as shown in figure 12-12.

will need to add allowances for edges and scams.

One dimension of the rectangle will be the height of the

A DRIP PAN is one of the objects you will have to

cylinder, and the other dimension will be its

make. Some of these pans, or boxes, will be used around

circumference. When you are given measurements for

the machinery in your shops. Take a look at them and

a cylindrical job, however, you will be given the

see how they were made. Some have welded seams.

diameter rather than the circumference of the cylinder.

Others are riveted and soldered. The welded seam is the

You will have to find the circumference yourself.

fastest and easiest to lay out, but the riveted and soldered

The circumference may be determined by

seam is by far the better of the two for sheet metal work.

computation or with a circumference rule.

The various methods of seaming will be discussed later

in this chapter.

Break out your layout tools. Select a piece of sheet

metal or template paper about 1 foot square. Lay out a

pan, or box, similar to that shown in figure 12-10. Make

the sides about 1 l/2 inches in height, and the bottom

about 9 inches square. Don't forget the tab if you are

going to join the seam by riveting. The angle for the

notch of the tab is 45 degrees (fig. 12-11). If this notch

Figure 12-11.--Layout of a box.

Figure 12-9.--Forming square and cylindrical shapes from

flat patterns.

Figure 12-10.--Layout of a box or a drip pan.

Figure 12-12.--Stretchout of a cylinder.

12-4