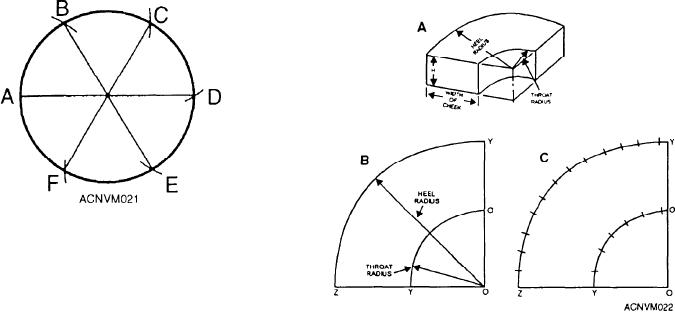

Figure 12-21.--Dividing a circle into six equal parts.

on the circumference for a beginning point. In figure

12-21, point A is selected for a beginning point. With

A as a center, swing an arc through the circumference

of the circle like the one shown at B in the illustration.

Figure 12-22.--Layout of a square or rectangular elbow.

Use B, then, as a point, and swing an arc through the

circumference at C. Continue to step off in this manner

sides of the elbow, the throat being the inside piece and

until you have divided the circle into six equal parts. If

the heel the outside piece. Set the dividers at exactly 1

the points of intersection between the arcs and the

inch, and step off the heel and throat arcs as shown in

circumference are connected as shown in figure 12-21,

view C of figure 12-22. If there is a distance of less than

the lines will intersect at the center of the circle, forming

1 inch left at the end of the arc, measure it with another

angles of 60 degrees.

pair of dividers or a scale. To make the stretchout of the

If you need an angle of 30 degrees, all you have to

heel and throat, lay out one piece of metal equal to the

do is to bisect one of these 60-degree angles by the

height of the elbow (H in view A, fig. 12-22) and equal

method described earlier in this chapter. Bisect the

in length to the number of steps taken with the dividers,

30-degree angle and you have a 15-degree angle. You

plus the fraction of an inch left over. One stretch out will

can construct a 45-degree angle in the same manner by

be the heel and the other the throat. You can assemble

bisecting a 9O-degree angle. In all probability, you'll

this elbow by welding, in which case you do not need

have a protractor to lay out these and other angles. But

to allow for tabs. But welding will cause a thin section

since you may not always have a steel square or

to warp, so you may need to use some of the other

protractor available, it's a good idea to know how to

standard methods for joining this type of work.

construct angles of various sizes and to erect

ALLOWING FOR EDGES

perpendiculars.

So far, your practice jobs have been laid out to be

LAY OUT A SQUARE OR RECTANGULAR

formed with the edges left as they are. Very few of your

ELBOW WITH A PAIR OF DIVIDERS. Take a look

jobs in the shop will actually be fabricated in this

at figure 12-22. View A shows you what the completed

manner. Edges are formed to improve the appearance

job should look like. Now, to make your layout for this

of the work, to strengthen the piece, or to eliminate a

job, draw the base line OZ shown in view B. Set the

raw edge that could cut someone. These edges may be

dividers for a distance equal to the width of the cheek.

formed from the metal itself by inserting wire or by

This distance forms the throat radius. This rule will not

attaching a band or angle iron. The kind of edge that you

always apply, as it must often be governed by the

will use on any job will be determined by the purpose,

amount of space available to make the turn with the

size, or strength of the edge needed.

elbow. Now, with O as a center, scribe the arc YU. To

get the heel radius, add the width of the cheek to the

The SINGLE-HEM EDGE is shown in figure

throat radius. Using 0 as a center, scribe the arc ZT.

12-23. This edge can be made in any width. In general,

These layouts, when cut, will form the cheeks, or sides,

the heavier the metal, the wider the hem is made. The

allowance for the hem is equal to its width (W in fig.

of the elbow. The next operation is to lay out the heel

12-23).

and throat pieces. These arc the other two of the four

12-8