seam is three times the width (W in fig. 12-28) of the

lock, one-half of this amount being added to each edge.

For example, if you are to have a 1/4-inch grooved

seam, 3 l/4 = 3/4 inch, which is the total allowance;

l/2 of 3/4 inch = 3/8 inch, which is the allowance you

will add to each edge.

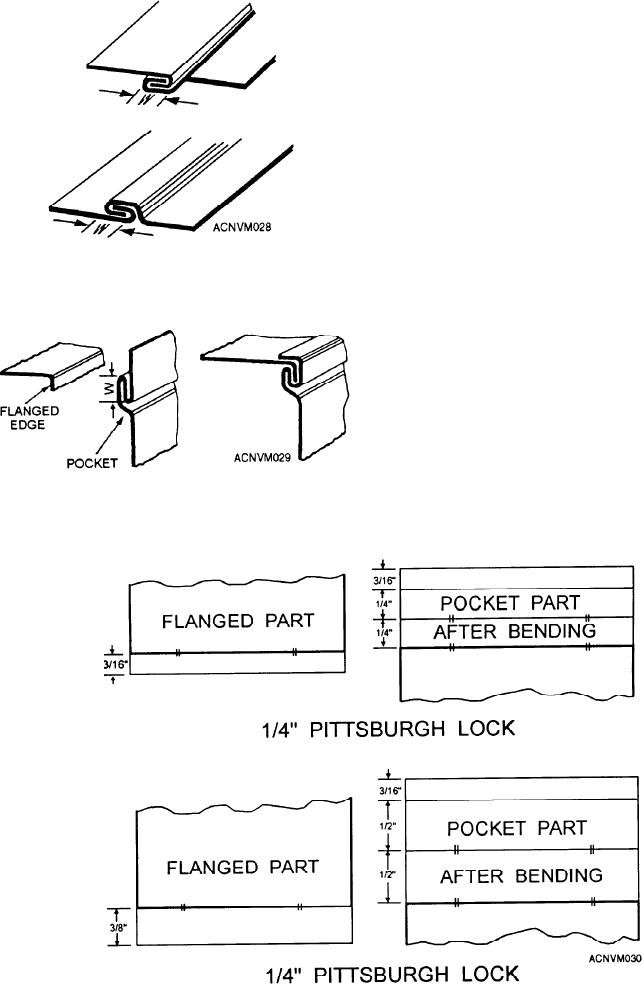

The PITTSBURGH LOCK SEAM (fig. 12-29) is a

very useful corner seam that is used to advantage in

rectangular ventilation lines, elbows, and boxes. At first

glance, the seam appears to be quite complicated, but

like lap and grooved seams it consists of only two

pieces. The two parts are the flanged edge and the

pocket with the projected edge, which is known as the

Figure 12-28.--Grooved seams.

locking flange after it has been bent over. After the

pocket is formed, the flanged edge is inserted into the

pocket, and the projected edge is then bent over the

flanged edge. It then forms the locking flange that

completes the Pittsburgh lock seam.

The allowance for the pocket and projected edge or

locking flange is W + W + 3/16 inch. W is the width or

depth of the pocket with 3/16 inch for the locking

flange. The width of the flanged edge is l/l6 inch less

than W to ensure a good tight fit. For example, if you

are laying out a l/4-inch Pittsburgh lock (fig. 12-30, top

Figure 12-29.--Pittsburgh lock seams.

view), your total allowance should be l/4 inch + l/4

inch + 3/16 inch, or 11/16 inch for the edge on which

Figure 12-30.--Layout of Pittsburgh lock seam.

12-10