PATTERN DEVELOPMENT

If all work that you were assigned to do consisted

of laying out and fabricating drip pans, boxes, lockers,

and straight sections of cylindrical and rectangular

ventilation lines, your work would be much easier. Your

layout would consist of nothing more than straight-line

angular development, allowances for seams and edges,

and visualizing the notch needed. But you will have to

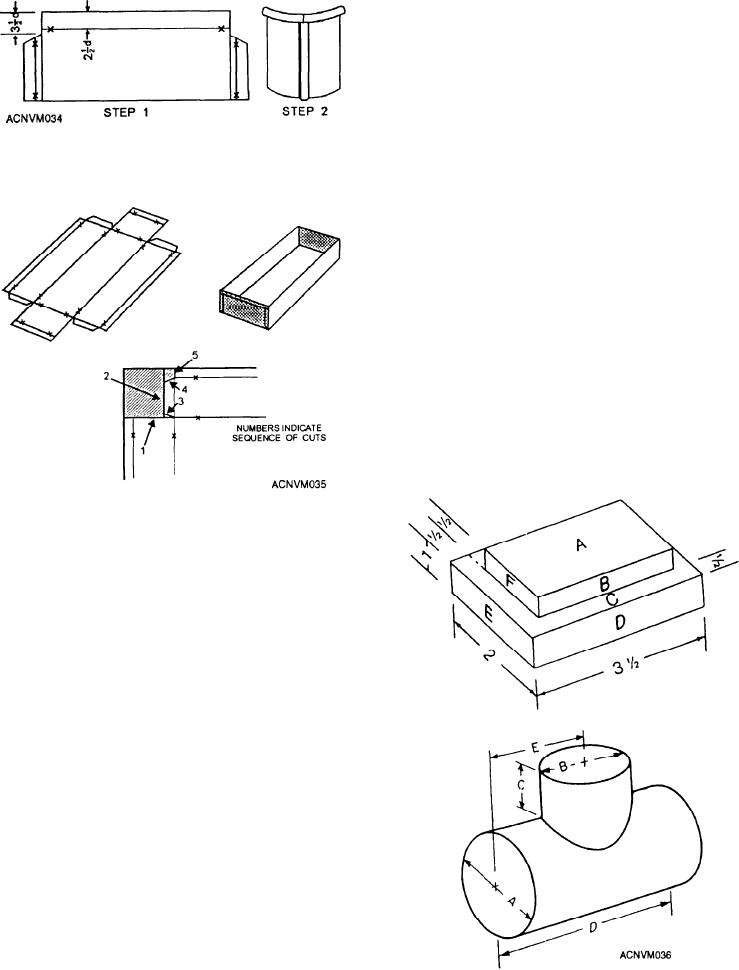

Figure 12-34.--Wire notch in cylindrical layout.

construct ventilation systems, or at least make repairs

to those systems. This work calls for elbows and tees,

which cannot be laid out unless you know how to do

parallel line development.

PARALLEL LINE METHOD

Parallel line development assumes that a line that is

parallel to another line is an equal distance from that

line at all points. The main lines of a structure to be laid

out by parallel line development are parallel to each

other. Objects that have opposite lines parallel to each

other, or that have the same cross-sectional shape

throughout their length, are developed by this method.

Figure 12-35.--Notching for an ice-cube tray.

A WIRE NOTCH is a notch used with a wired edge.

The wire-edge cut-back allowance from the edge of the

pattern will be one wire's diameter more than the depth

of the allowance for the wired edge (2 1/2d), or 3 l/2

times the diameter of the wire (3 1/2d). The allowance

on each side of the stretchout for the grooved seam is

equal to 1 1/2 times the width of the seam (1 1/2W).

That portion of the notch next to the wired edge will be

straight, as shown figure 12-34. The shape of the notch

on the seam will depend upon the type of seam used.

The grooved seam shown in figure 12-34 requires a

45-degree notch.

Most of your work will require more than one type

of notch. For example, in figure 12-34, notches are

required for the wired edge and the grooved seam.

You will find another combination of notches when

you lay out and make an ice-cube tray. The tray itself is

similar to the drip pan you have already laid out, but the

upper edge will require a wired edge. In this job, you

will have to use the wire notch, the modified V, and the

Figure 12-36.--Overall view of some objects fabricated by the

parallel line method.

square notch (fig. 12-35).

12-12