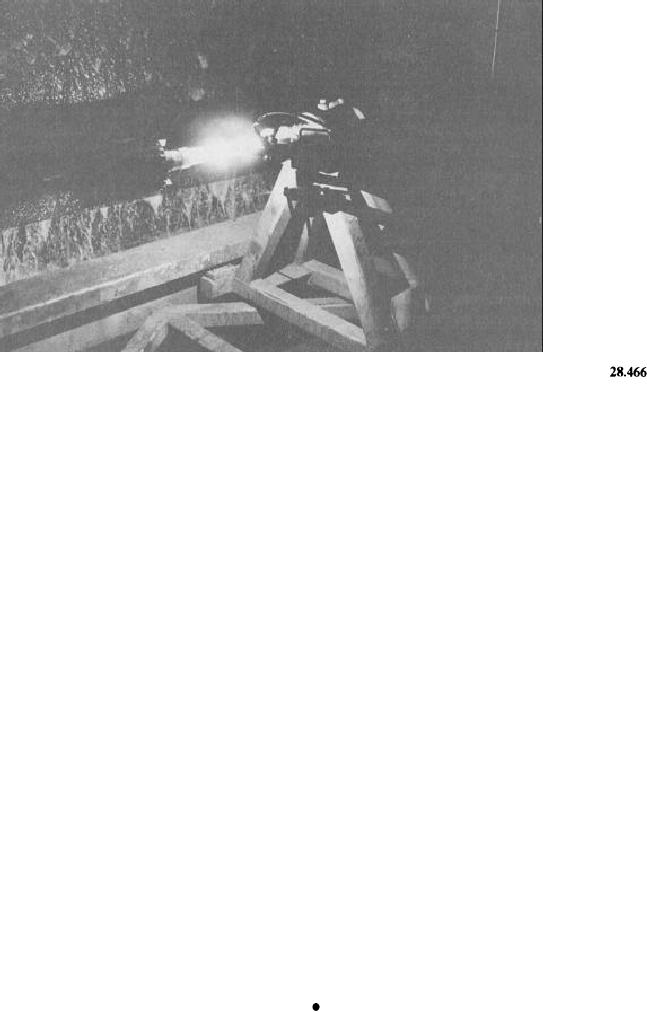

Figure 12-9.--A shaft being thermal sprayed.

techniques can pull out particles, producing a severely

be free of defects such as cracks, chips, blisters or

pitted surface or heat checking. It is essential that the

loosely adhering particles, oil or other contaminants

sprayed particles be cleanly sheared and not pulled from

that bleed out through the coating, pits exposing the

the surface by the finishing operation.

undercoat or substrate, and coating separation. The item

will be checked for correct dimensions.

Generally, wet grinding is better than dry grinding

if you use the proper wheel. Use wheels with coarse

grain and low bond strength to grind sprayed coatings;

CONTACT ELECTROPLATING

this prevents loading the wheel. When you use a

Contact (brush-on) electroplating is also called

coolant, try to get one with a rust inhibitor and keep it

contact plating. It is a method used to deposit metal from

clean and free of foreign matter.

concentrated electrolyte solutions without the use of

Always consult and follow the coating manu-

immersion tanks. The solution is held in an absorbent

facturer's finishing recommendations when you select

material attached to the anode lead of a dc power pack

the finishing technique, including the proper tool, feeds,

The cathode lead of the power pack is connected to the

workpiece to provide the ground and complete the

and speeds.

plating circuit. Electroplating deposits metal when the

absorbent material on the anode contacts the work area.

QUALITY ASSURANCE

Constant motion between the anode and the work is

required to produce high-quality, uniform deposits.

In-process inspection of each sprayed component

Contact electroplating can be used effectively on

shall assure, as a minimum, verification of the

small to medium size areas to perform the same

anchor-tooth prepared surface with a profile tape test;

functions as bath plating. Some examples are corrosion

no moisture, oil, grit, contaminants, blisters, cracks,

protection, wear resistance, lower electrical contact

chips, pits, or coating separation are present before or

resistance, and repair of worn or damaged machine

during spraying; coating thickness per pass conforms to

parts. This process is not recommended to replace bath

the procedure, if this is an essential element; and the

plating. However, electroplating is superior to bath

coating manufacturer's recommended temperature

plating in some situations, most of which are in the

range is maintained.

following list:

As a minimum, the end item inspection of sprayed

coating will include a visual examination. The finished

The equipment is portable; plating can often be

coating, when examined with a 10X magnification, will

done at the job site.

12-7