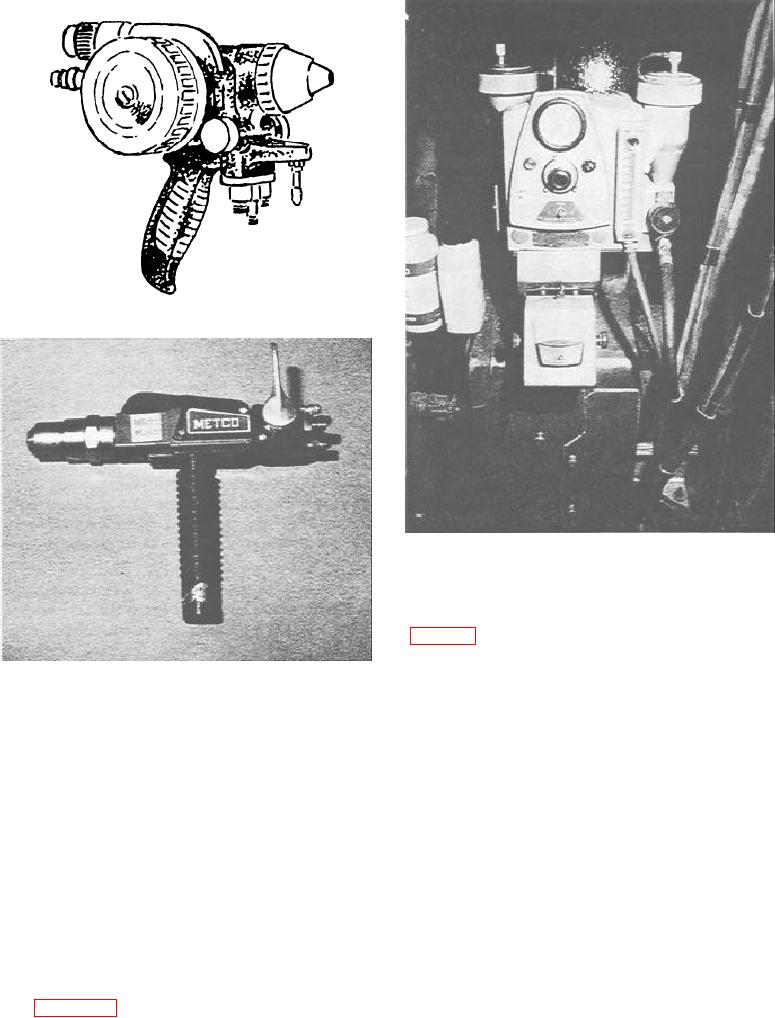

Figure 12-2.--Type 12E spray gun.

28.464

Figure 12-4.--Power feed unit.

(fig. 12-4). The powder is propelled through the flame

where it melts and is deposited on the work in the form

of a coating. This gun will spray metal, ceramic, cement,

28.463

and exothermic powders.

Figure 12-3.--Type 6P-II powder spray gun.

Exothermic coating composites are materials that

produce an exothermic (heat evolved) reaction from

their chemical creation. For example, when nickel and

a self-contained compressed air turbine. At the nozzle,

aluminum composites reach a certain temperature in the

the wire is continually melted in an oxygen-fuel gas

spray gun flame, they combine to produce nickel

flame. Then, a controlled stream of compressed air

aluminite and heat. The extra heat provided to the

blasts the molten tip of the wire, producing a fine metal

molten particles by the exothermic reaction, coupled

spray. Systems of this type are commonly used to spray

with the high particle velocity of the thermal spray

aluminum wire coatings for corrosion control on items

process, accounts for the self-bonding characteristics of

deck machinery, and equipment foundations.

the coating and its exceptional strength.

Exothermic materials are often called one-step

coatings. They produce self-bonding, one-step buildup

Powder-Oxygen-Fuel Spray

coatings that combine metallurgical bonding with good

wear resistance. They also eliminate the need for

Figure 12-3 shows a type 6P-II powder spray gun.

The powder is fed into the gun by a powder feed unit

separate bond and buildup coatings.

12-3