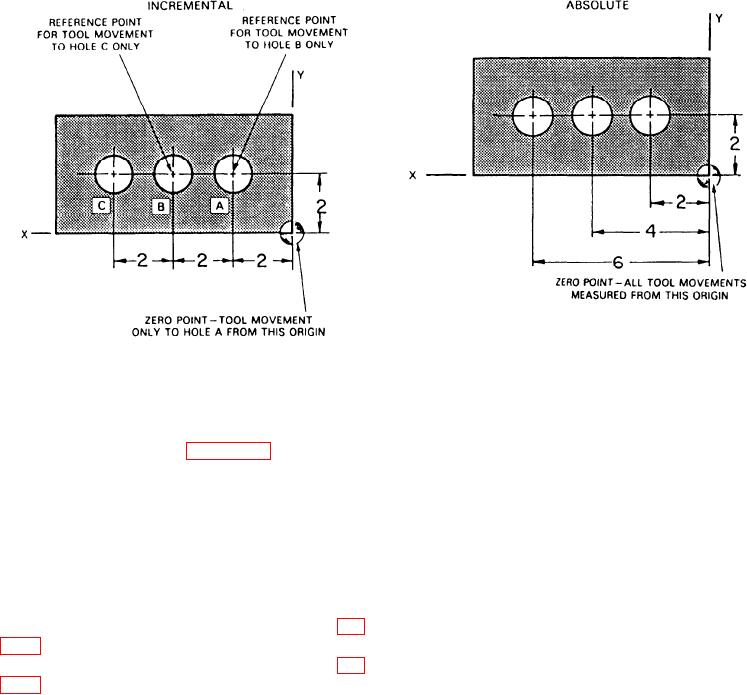

Figure 11-12.--Absolute positioning system.

Figure 11-11.--Incremental positioning system.

location. Home zero is usually, but not always, located

at the tool change position of a machining center. A part

Spindle motion is assigned the Z axis. This means

is programmed independent of the machine coordinate

that for a drill press or vertical milling machine the Z

system. The programmer will pick a location on the part

axis is vertical, as shown in figure 11-10. For machines

or fixture. This location becomes the origin of the

such as lathes or horizontal milling machines, the Z axis

coordinate system for that part. The programmer's

is horizontal.

coordinate system is called the local or part coordinate

system. The machine coordinate system and the part

POSITIONING SYSTEMS

coordinate system will almost never coincide. Before

running the part program, the coordinate system must

There are two ways that machines position

be transferred from the machine system to the part

themselves with respect to their coordinate systems.

system. This is known as setting a zero point. In other

These systems are called incremental positioning and

words, the machine has a zero point that is already

absolute positioning. With incremental positioning (fig.

programmed into it, but you can place the part to be

11-11) each tool movement is made with reference to

machined either in the chuck or on the table and

the prior or last tool position. Absolute positioning (fig.

establish your zero point, and then the machine will use

11-12) measures all tool movement from a fixed point,

that point as its zero point. This eliminates having to use

origin, or zero point. Use absolute dimensioning where

fixtures and other complicated setups. You just put your

possible because a mistake on the dimensions at one

work in the machine and by using the proper codes you

point will not be carried over to the dimensions at other

tell the machine where the zero point is located.

points. It is also easier to check for errors.

As stated earlier in the chapter, this has only been a

brief overview of CNC. It is a complicated subject that

SETTING THE MACHINE ORIGIN

many books have been written about. To cover it

completely you will need to have formal training and

Most CNC machinery has a default coordinate

extensive on-the-job training. As the Navy expands into

system the machine assumes upon power-up, known as

the world of CNC this training will become more

the machine coordinate system. The origin of this

system is called the machine origin or home zero

readily available.

11-9