because it is inconvenient or the necessary equipment

is not available. To help ensure a quality job, be sure

you use the required equipment and prepare the surface

carefully and thoroughly.

Surface preparation includes three distinct opera-

tions: (1) cleaning, (2) undercutting, and (3) surface

roughening. We will discuss each of them in the next

paragraphs.

Cleaning

You must ensure a good bond between the sprayed

coating and the base material to which it is applied. To

do that, be sure the areas to be coated and the adjacent

areas are free from oil, grease, water, paint, and other

foreign matter that may contaminate the coating.

SOLVENT CLEANING.--Before blasting or

spraying, use solvent to clean all surfaces that have

come in contact with any oil or grease. (Vapor

degreasing is preferred, but you may use solvent

washing.) When using solvent, be very careful that it is

not strong enough to attack the base material; do NOT

leave any residue on the surfaces. Trichloroethane and

28.465

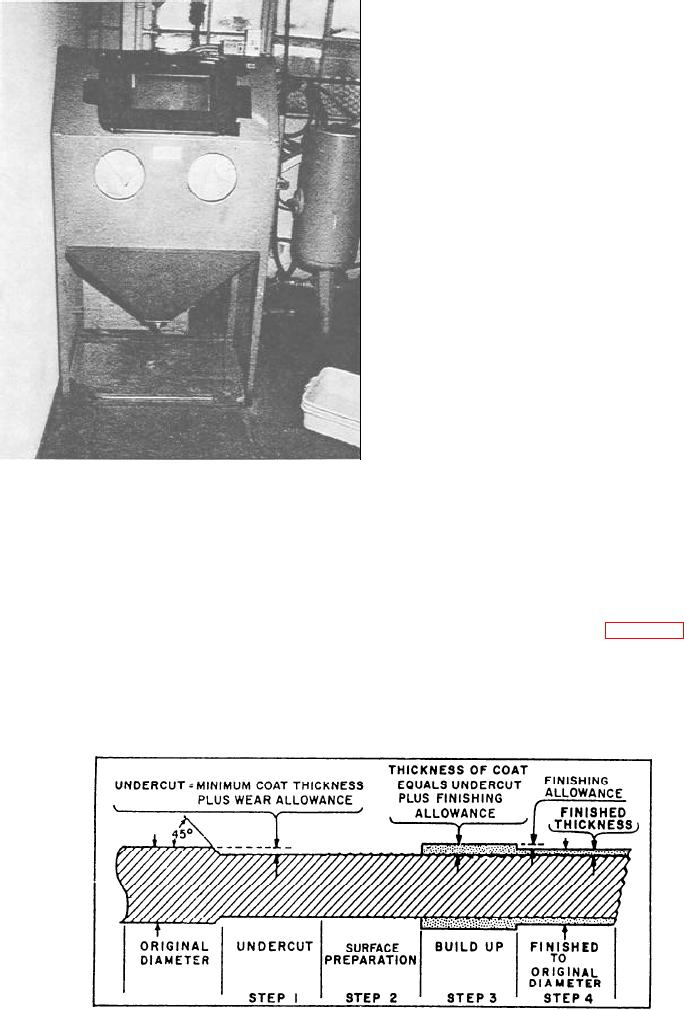

Figure 12-5.--A typical sandblaster.

toluene are suitable solvents. Most solvents are

flammable and toxic, so you must follow proper pre-

PREPARING THE SURFACES

cautions when you use them. You also must be very

careful to protect any parts that may be attacked by the

Surface preparation is often the most critical part of

solvents.

the job, yet it often gets the least attention. We cannot

ABRASIVE CLEANING.--You can use a sand

overemphasize its importance because an improperly

blaster such as the one shown in figure 12-5 to remove

prepared surface will cause the part to fail under

heavy or insoluble deposits. Be sure to follow your

operating conditions. For this reason, even the best and

operator's manual. Do not use the same abrasive

most elaborate preparation is still the cheapest part of

blasting equipment to roughen surfaces that you use for

general cleaning.

the job. Quite often, surfaces are not prepared properly

Figure 12-6.--Major steps in restoration of dimensions with thermal spray.

12-4