HEAT CLEANING.--Use a solvent to clean

porous materials that have been contaminated with

grease or oil. Then, heat them for 4 hours to char and

drive out foreign materials from the pores. Heat steel

alloys at 650F maximum; heat aluminum alloys at

300F maximum. Do not heat age-hardening alloys. In

thin sections, use lower temperatures to minimize

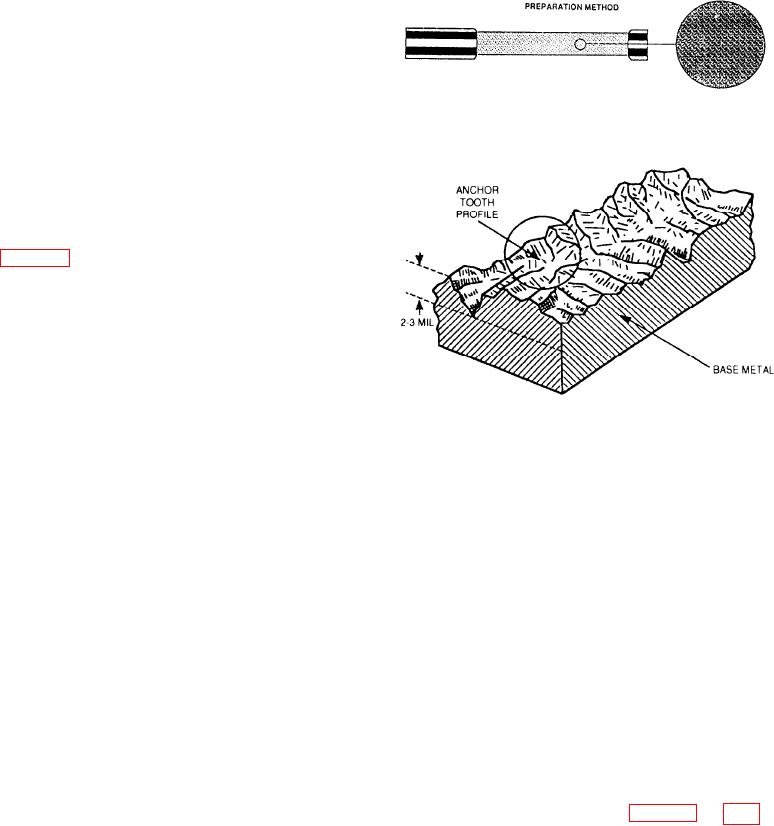

Figure 12-7.--A 2- to 3-mil anchor-tooth profile.

warpage.

Undercutting

In undercutting, you remove enough of the surface

of the metal to be built up to ensure a satisfactory

thickness of metalized deposit on the finished job. (See

fig. 12-6.) Undercutting must be a dry machining

operation; any cutting lubricants or coolants used will

contaminate the surface of the workpiece. When you

build up shafts, be sure the undercut section is con-

centric to the original axis of the shaft. The length of the

undercut should extend beyond both ends of the sleeve

or bearing, the limits of the carbon or labyrinth ring, or

the packing gland in which the shaft will operate.

However, you must be careful not to remove any fillets

Figure 12-8.--Profile of an anchor-tooth pattern.

at points where the shaft section diameter changes. The

ends of the undercut should be at 15 to 45 degrees to the

base metal.

Do NOT use a lubricant or coolant during the under-

cutting and roughening process. Keep the surface clean

Several factors determine the depth to which you

and dry; you can contaminate it if you touch it with your

should undercut a shaft. Some of them are severity of

hands. If the surface becomes contaminated, you must

service, the amount of wear expected in service, the

thoroughly clean and degrease it. The cleanliness and

depth of metal loss, the remaining thickness of the load-

roughness greatly affect the strength of the bond

carrying member, and the limits of the coating you will

between the base metal and the sprayed coating. Two

use. In general, the minimum specified depth of the

methods of surface roughening are (1) abrasive blasting

undercut should be at least equal to the recommended

and (2) macroroughening. Use the latter method to

minimum thickness of the coating, plus the wear or

restore dimensions greater than 1/2 inch where you

corrosion tolerance for the application.

cannot use exothermic materials.

Undercutting reduces the effective structural cross

ABRASIVE BLASTING.--Before thermal

section of the part to be metalized. Also, sharp grooves

spraying, use abrasive blasting to condition the surfaces

and shoulders without a fillet or radius may produce

to be coated. Blasting must not be so severe as to distort

stress risers. A stress riser is a spot on a part where

the part. The required depth of surface roughness is

stresses have been set up that may cause the part to fail.

related to the configuration (size and shape) of the part.

When you prepare for thermal spraying, carefully

Where part configuration permits, use a roughness

examine the workpiece from a design standpoint.

profile of 2 to 3 mils (as shown in figs. 12-7 and 12-8).

Consider all parts that will be subjected to high stresses,

When this depth may cause distortion because of the

shock loads, or critical applications to be sure the

part configuration, you can reduce the anchor-tooth

structure maintains adequate strength. You cannot

pattern to a 1-mil profile.

depend upon metal spray deposits to restore qualities

The blasting particles recommended for surface

such as tensile strength or resistance to fatigue stress.

preparation are angular nonmetallic grit (for example,

aluminum oxide) and the recommended mesh size is 16.

Surface Roughening

When a grit is designated for surface preparation, it

After undercutting the shaft, you must roughen the

must remain clean, so do not use it for any other

undercut section to provide a bond for the metal spray.

purpose.

12-5