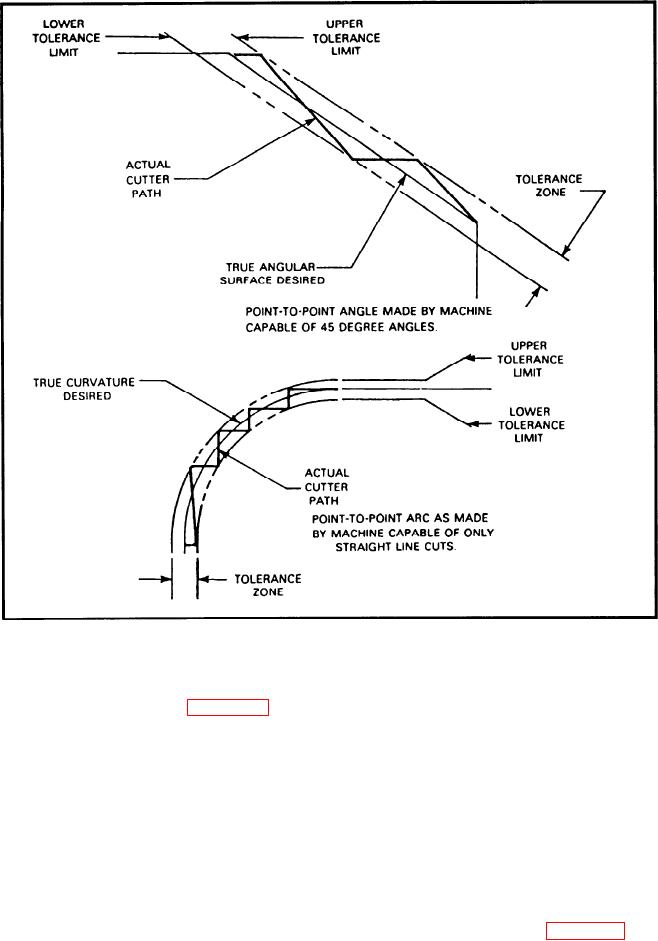

Figure 11-7.--Point-to-point angles and arcs.

Point-to-point machines move only in straight

manufactured by the same company. Figure 11-6 shows

lines. They are limited in a practical sense to hole

a typical controller. Each controller is manufactured

with a standard set of built-in codes. Other codes are

straight milling cuts parallel to a machine axis. When

added by the machine tool builders. For this reason,

making an axis move, all affected drive motors run at

program codes differ somewhat from machine to

the same speed. When one axis motor has moved the

machine. Every CNC machine, regardless of manu-

instructed amount, it stops while the other motor

facture, is a collection of systems coordinated by the

continues until its axis has reached its programmed

controller.

location. This makes the cutting of 45-degree angles

possible, but not arcs or angles other than 45 degrees.

TYPES OF CONTROL SYSTEMS

Arcs and angles must be programmed as a series of

straight line cuts, as shown in figure 11-7.

There are two types of control systems used on NC

A continuous-path machine can move its drive

machines: point-to-point systems and continuous-path

motors at varying rates of speed while positioning the

systems.

machine. Therefore, it can more easily cut arcs and

11-7