other setscrew, bearing on the end of the cutter, is for

adjusting the cutter to the work.

Part B of figure 6-67 shows a boring bar fitted

with a two-edge cutter held by a taper key. This is

more of a finishing or sizing cutter, as it cuts on both

sides and is used for production work.

The boring bar shown in part C of figure 6-67 is

fitted with a cast iron head to adapt it for boring work

of large diameter. The head is fitted with a fly cutter

similar to the one shown in part A. The setscrew with

the tapered point adjusts the cutter to the work.

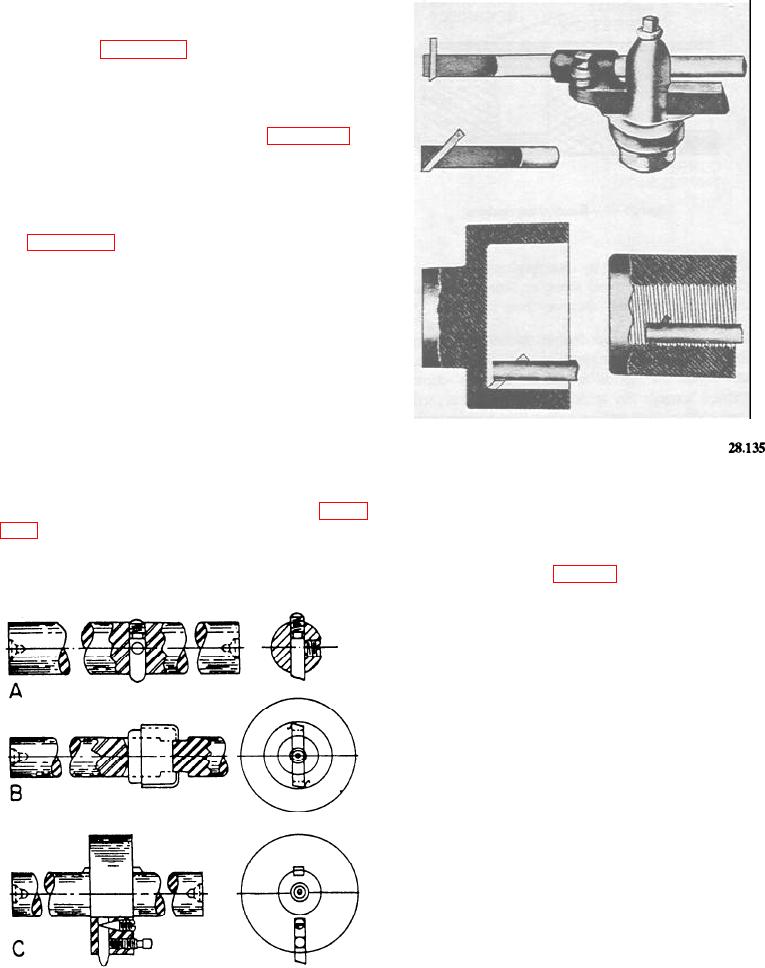

Figure 6-68 shows a common type of boring bar

holder and applications of the boring bar for boring

and internal threading. When threading is to be done

in a blind hole, it sometimes becomes necessary to

undercut or relieve the bottom of the hole. This will

enable mating parts to be screwed all the way to the

shoulder and make the threading operation much

easier to do.

KNURLING

Knurling is the process of rolling or squeezing

Figure 6-68.--Application of boring bar holder.

impressions into the work with hardened steel rollers

that have teeth milled into their faces. Examples of

the various knurling patterns are shown in figure

the metal is raised by the forming action of the knurl

6-17. Knurling provides a gripping surface on the

rollers.

work; it is also used for decoration. Knurling

increases the diameter of the workpiece slightly when

The knurling tool (fig. 6-16) is set up so the faces

of the rollers are parallel to the surface of the work

and with the upper and lower rollers equally spaced

above and below the work axis or center line. The

spindle speed should be about half the roughing speed

for the type of metal being machined. The feed

should be between 0.015 inch and 0.025 inch per

revolution. The work should be rigidly mounted in

the tailstock to help offset the pressure exerted by the

knurling operation.

The actual knurling operation is simple if you

follow a few basic rules. The first step is to make sure

that the rollers in the knurling tool turn freely and are

free of chips and imbedded metal between the cutting

edges. During the knurling process, apply an ample

supply of oil at the point of contact to flush away

chips and provide lubrication. Position the carriage

so that one-third to one-half of the face of the rollers

extends beyond the end of the work. This eliminates

part of the pressure required to start the knurl

impression. Force the knurling rollers into contact

with the work. Engage the spindle clutch. Check the

Figure 6-67.--Various boring bars.

knurl to see if the rollers have tracked properly, as

6-39