wheels are mounted on tapered shafts, known as

quills, to grind internal surfaces.

The grinding wheel speed is changed by using

various sizes of pulleys on the motor and spindle

shafts. An instruction plate on the grinder gives both

the diameter of the pulleys required to obtain a given

speed and the maximum safe speed for grinding

wheels of various diameters. Grinding wheels are

safe for operation at a speed just below the highest

recommended speed. A higher than recommended

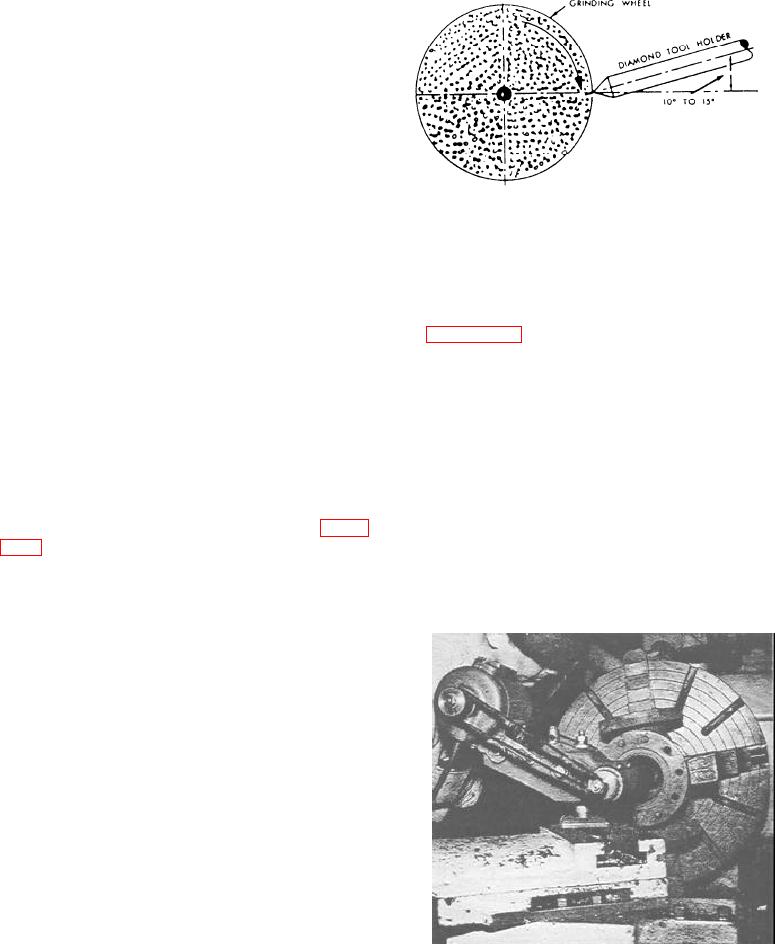

Figure 6-73.--Position of the diamond dresser.

speed may cause the wheel to disintegrate. For this

reason, wheel guards are furnished with the toolpost

grinder to protect against injury.

whether the feed should be increased or decreased.

Never stop the work or the grinding wheel while they

Always check the pulley combinations given on

are in contact with each other.

the instruction plate of the grinder when you mount a

wheel. Be sure that the combination is not reversed,

Figure 6-74 illustrates refacing the seat of a

because this may cause the wheel to run at a speed far

high-pressure steam valve that has a hard,

in excess of that recommended. During all grinding

Stellite-faced surface. The refacing must be done

operations, wear goggles to protect your eyes from

with a toolpost grinder. Be sure that all inside

flying abrasive material.

diameters run true before starting the machine work.

Before you use the grinder, dress and true the

Spindle speed of the lathe should be about 40 rpm or

wheel with a diamond wheel dresser. The dresser is

less. Too high a speed will cause the grinding wheel

held in a holder that is clamped to the chuck or

to vibrate. Set the compound rest to correspond with

faceplate of the lathe. Set the point of the diamond at

the valve seat angle. Use the cross-slide hand feed or

center height and at a 10 to 15 angle in the direction

the micrometer stop on the carriage for controlling the

of the grinding wheel rotation, as shown in figure

depth of cut; use the compound rest for traversing the

6-73. The 10 to 15 angle prevents the diamond

grinding wheel across the work surface. Remember,

from gouging the wheel. Lock the lathe spindle by

whenever you grind on a lathe, always place a cloth

placing the spindle speed control lever in the low rpm

across the ways of the bed and over any other

position. (NOTE: The lathe spindle does not revolve

when you are dressing the grinding wheel.)

Bring the grinding wheel into contact with the

diamond dresser by carefully feeding the cross-slide

in by hand. Move the wheel slowly by hand back and

forth over the point of the diamond, taking a

maximum cut of 0.0002 inch. Move the carriage if

the face of the wheel is parallel to the ways of the

lathe. Move the compound rest if the face of the

wheel is at an angle. Make the final depth of cut of

0.0001 inch with a slow, even feed to obtain a good

wheel finish. Remove the diamond dresser holder as

soon as you finish dressing the wheel and adjust the

grinder to begin the grinding operation.

Rotate the work at a fairly low speed during the

grinding operation. The recommended surface speed

is 60 to 100 fpm. The depth of cut depends upon the

hardness of the work, the type of grinding wheel, and

the desired finish. Avoid taking grinding cuts deeper

28.136

than 0.002 inch until you gain experience. Use a

Figure 6-74.--Refacing seat of high-pressure steam valve.

fairly low rate of feed. You will soon be able to judge

6-41