taper. If you bear this in mind when machining

machined surfaces that could become contaminated

tapers, you will not go wrong. Use the formula:

from grinding dust.

TPF = TPI 12

TAPERS

Taper is the gradual decrease in the diameter of

where:

thickness of a piece of work toward one end. To find

the amount of taper in any given length of work,

TPF = TAPER PER FOOT

subtract the size of the small end from the size of the

large end. Taper is usually expressed as the amount of

TPI = TAPER PER INCH

taper per foot of length, or as an angle. The following

examples explain how to determine taper per foot of

Other formulas used in figuring tapers are as follows:

length.

T

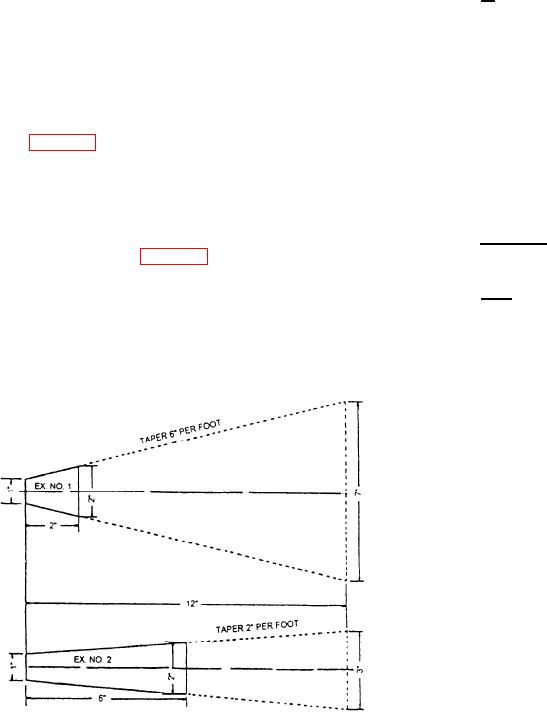

EXAMPLE 1: Find the taper per foot of a piece

TPI = L

of work 2 inches long: Diameter of the small end is 1

inch; diameter of the large end is 2 inches.

where:

The amount of the taper is 2 inches minus 1 inch,

which equals 1 inch. The length of the taper is given

TPI = TAPER PER INCH

as 2 inches. Therefore, the taper is 1 inch in 2 inches

of length. In 12 inches of length it would be 6 inches.

T = TAPER (Difference between large and

(See fig. 6-75).

small diameters, expressed in inches)

EXAMPLE 2: Find the taper per foot of a piece 6

inches long. Diameter of the small end is 1 inch;

L = LENGTH of taper, expressed in inches

diameter of the large end is 2 inches.

L TPF

The amount of taper is the same as in example 1;

and T = TPI L (in inches)

T

= 12

that is, 1 inch. (See fig. 6-75.) However, the length

of this taper is 6 inches; hence the taper per foot is

1 inch 12/6 = 2 inches per foot.

TPF

T P I = 12

From the foregoing, you can see that the length of

a tapered piece is very important in computing the

Tapers are frequently cut by setting the angle of

the taper on the appropriate lathe attachment. There

are two angles associated with a taper-the included

angle and the angle with the center line. The included

angle is the angle between the two angled sides of the

taper. The angle with the center line is the angle

between the center line and either of the angled sides.

Since the taper is turned about a center line, the angle

between one side and the center line is always equal to

the angle between the other side and the center line.

Therefore, the included angle is always twice the

angle with the center line. The importance of this

relationship will be shown later in this chapter.

There are several well-known tapers that are used

as standards for machines on which they are used.

These standards make it possible to make or get parts

to fit the machine in question without detailed

measuring and fitting. By designating the name and

number of the standard taper being used, you can

immediately find the length, the diameter of the small

Figure 6-75.--Tapers.

and large ends, the taper per foot, and all other

6-42