Figure 6-64.--Machining to a shoulder.

scribe the exact location of the shoulder on the work.

Next, use a parting tool to machine a groove 1/32 inch

from the scribe line toward the smaller finish diameter

end and 1/32 inch larger than the smaller finish

diameter. Then, take heavy cuts up to the shoulder

made by the parting tool. Finally, take a finish cut

from the small end to the should scribe line. This

procedure eliminates detailed measuring and speeds

up production.

PARTING AND GROOVING

One of the methods of cutting off a piece of stock

while it is held in a lathe is a process called parting.

This process uses a specially shaped tool with a

cutting edge similar to that of a square nose tool. The

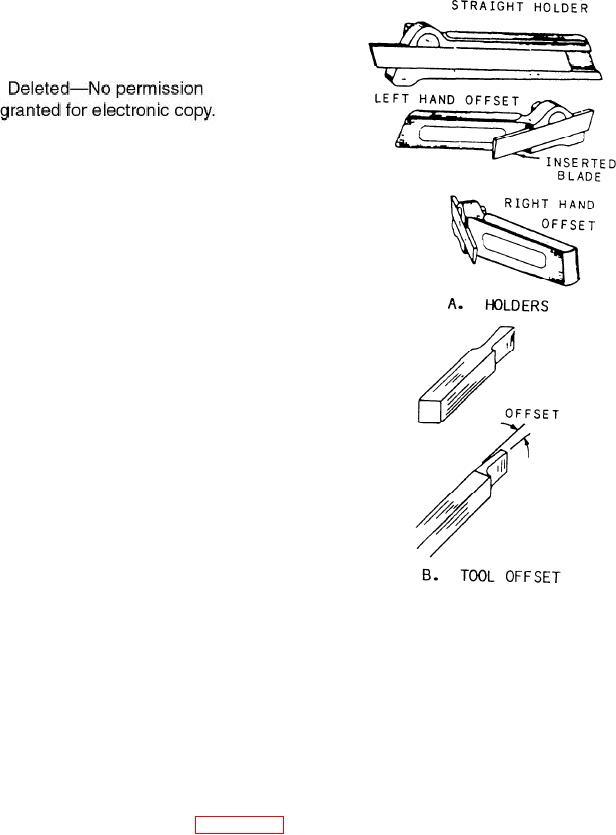

Figure 6-65.--Parting tools.

parting tool is fed into the rotating work,

perpendicular to its axis, cutting a progressively

deeper groove as the work rotates. When the cutting

edge of the tool gets to the center of the work being

be parted with the point at which the parting is to

parted, the work drops off as if it were sawed off.

occur as close as possible to the chuck jaws. Always

Parting is used to cut off parts that have already been

make the parting cut at a right angle to the centerline

machined in the lathe or to cut tubing and bar stock to

of the work. Feed the tool into the revolving work

required lengths.

with the cross-slide until the tool completely

separates the work.

Parting tools can be the inserted blade type or can

be ground from a standard tool blank. They may also

Cutting speeds for parting are usually slower than

be brazed on carbide or carbide inserts. Figure 6-65

turning speeds. You should use a feed that will keep a

shows two basic types of parting tools. For the tool to

thin chip coming from the work. If chatter occurs,

have maximum strength, the length of the cutting

decrease the speed and increase the feed slightly. If

portion of the blade that extends from the holder

the tool tends to gouge or dig in, decrease the feed.

should be only slightly greater than half the diameter

of the work to be parted. The end cutting edge of the

Grooves are machined in shafts to provide for tool

tool must feed directly toward the center of the

runout in threading to a shoulder, to allow clearance

workpiece. To ensure this, place a center in the

for assembly of parts, to provide lubricating channels,

tailstock and align the parting tool vertically with the

or to provide a seating surface for seals and O-rings.

tip of the center. The chuck should hold the work to

6-37