TM 55-2815-574-24

0023

PERFORM FUEL SPILL BACK TEMPERATURE TEST - Continued

CORRECTIVE ACTION - Continued

1.

Start engine (TM 55-1925-205-10).

2.

Operate engine for 10 minutes after normal operating temperature has been reached.

3.

Shut engine down (TM 55-1925-205-10).

4.

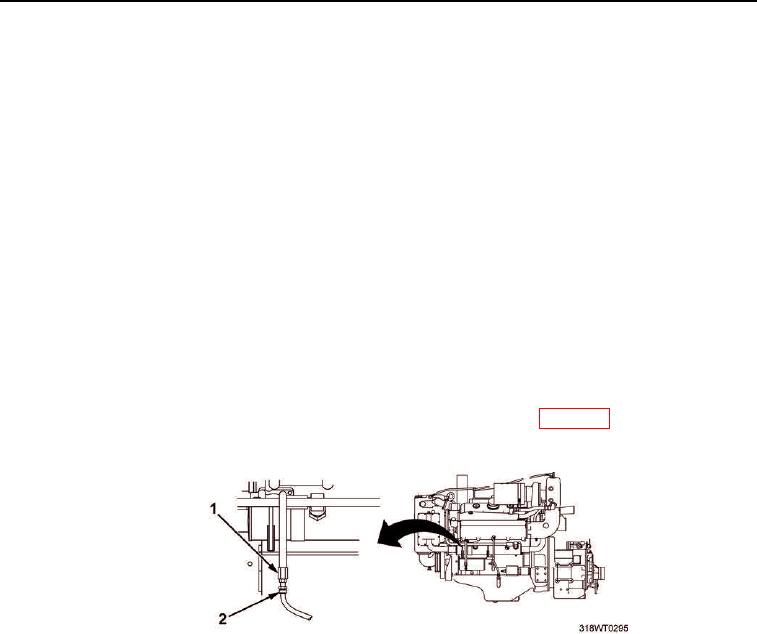

Position drain pan under fuel return line (Figure 5, Item 1).

5.

Disconnect fuel return line (Figure 5, Item 1) from fitting (Figure 5, Item 2).

6.

Start engine and run for several seconds allowing an inch of fuel to accumulate in drain pan.

7.

Using a thermometer, measure temperature of fuel.

NOTE

If the fuel temperature exceeds 150F (66C), 8 percent horsepower will be lost

for every 20F increase. (Metric conversions, on increasing increments, are not

proportional to standard temperatures.)

8.

Verify the fuel temperature is below 150F (66C).

9.

If fuel temperature is above 150F (66C), Replace fuel cooler (WP 0081).

10.

Connect fuel return line (Figure 5, Item 1) to fitting (Figure 5, Item 2).

Figure 5. Fuel Return Line.

11.

Remove drain pan and dispose of contents in accordance with local procedure.

12.

Clean up spilled fluid with spill clean-up kit and dispose of spill clean-up kit waste in accordance

with local procedure.

END OF WORK PACKAGE