TM 55-2815-574-24

0024

PRESSURE TEST FRESH WATER COOLING SYSTEM - Continued

CORRECTIVE ACTION - Continued

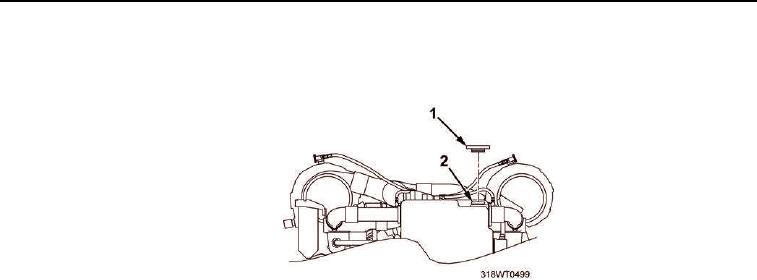

Figure 1. Heat Exchanger Pressure Cap.

2.

Using radiator test kit, pressurize cooling system to 15 to 20 PSI (103 to 138 kPa).

3.

Observe the system pressure on tester.

4.

If a measurable pressure drop is detected, examine entire cooling system for a possible

external or internal leak. Repair if necessary.

5.

Release pressure.

6.

Remove tester from heat exchanger.

7.

Install pressure cap adapter (Figure 2, Item 3) to the pressure tester (Figure 2, Item 2).

8.

Install pressure cap (Figure 2, Item 1) on cap adapter (Figure 1, Item 3).

9.

Apply 15 to 20 PSI (103 to 138 kPa) pressure to pressure cap (Figure 2, Item 1) and hold for 10

minutes.

NOTE

If the pressure cap releases early or late, the pressure cap must be replaced.

10.

Observe the cap release pressure at 15 PSI (130 kPa).

11.

Remove pressure tester (Figure 2, Item 2) and cap adapter (Figure 2, Item 3) from pressure cap

(Figure 2, Item 1).