TM 55-2815-574-24

0061

INSPECTION - Continued

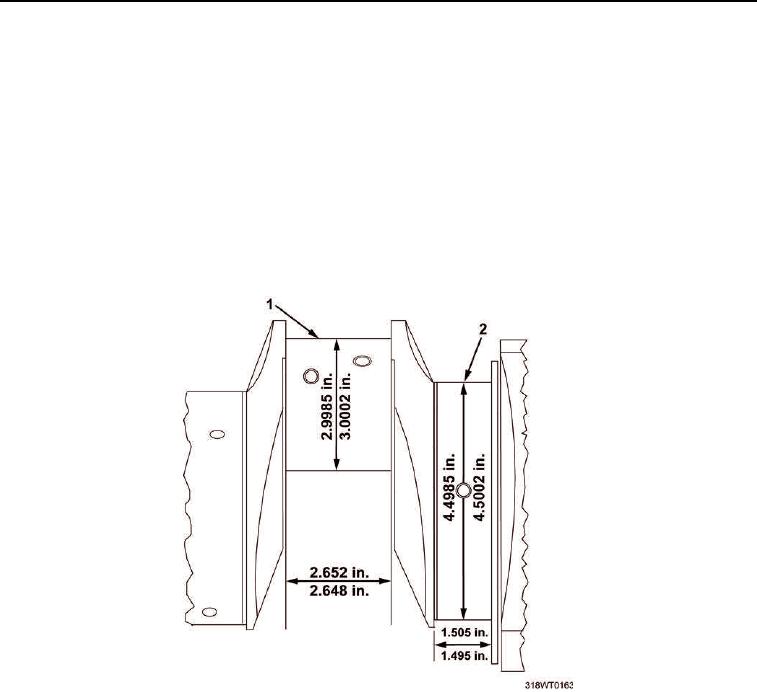

e.

Crankshaft maximum connecting rod journal (Figure 4, Item 1) or main bearing journal

(Figure 4, Item 2) to bearing clearance, with new bearings, should not exceed 0.0045 (0.01143 cm) on

the connecting rod bearings, 0.0002 in. (0.0051 cm) and 0.0055 in. (0.01397 cm) on the main

bearings, 0.0015 in. (0.00381 cm). Replace crankshaft if out of tolerance.

f.

Main bearing journal (Figure 4, Item 2) taper should not exceed 0.0004 in. (0.01143 cm). Replace

crankshaft if out of tolerance.

g.

Main bearing (Figure 4, Item X) out-of-round should not exceed 0.0005 in. (0.00127 cm). Replace

crankshaft if out of tolerance.

h.

Measure the new bearing thickness, it should be 0.1548 in. (0.3932 cm) 0.0003 in. (0.000762 cm).

i.

Measure the old bearing thickness, it should be a minimum of 0.1540 in. (0.3912 cm).

Figure 4. Crankshaft Journal Specifications.

8.

Inspect the crankshaft stabilizers for cracks, discoloration, out of shape or excessive wear, replace as

necessary.

9.

Inspect woodruff keys (Figure 5, Item 1) for damage. Repair if necessary.

10.

Inspect plugs (Figure 5, Item 1) for damage. Repair if necessary.

END OF TASK