TM 55-2815-574-24

0061

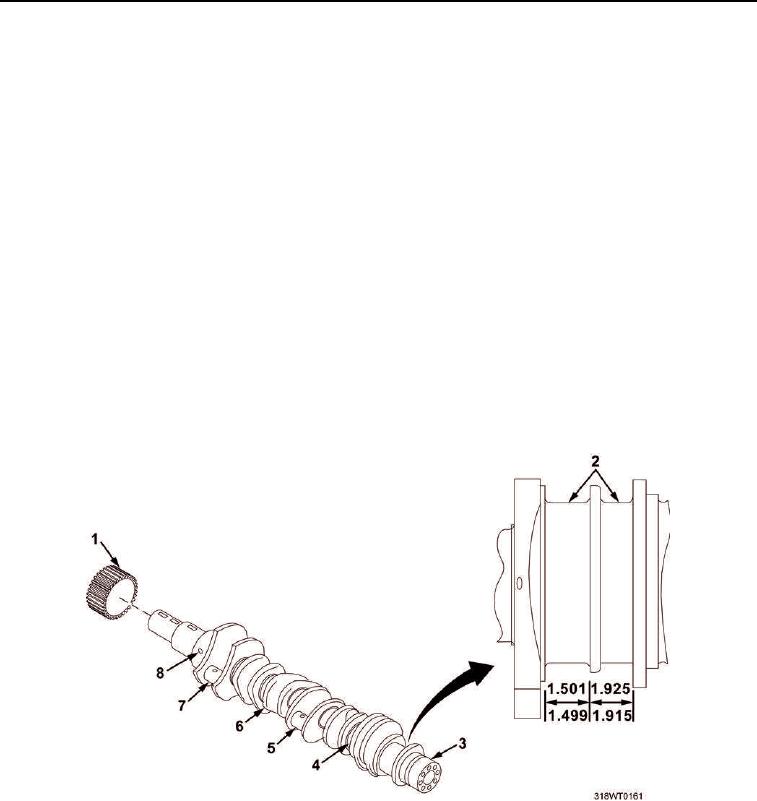

INSPECTION

1.

Check crankshaft (Figure 2, Item 6), journal surfaces (Figure 2, Items 7 and 4) and oil passages

(Figure 2, Item 8) for cracks using magnetic particle inspection or equivalent. Replace crankshaft if damage

is found.

2.

Check crankshaft (Figure 2, Item 6) for discoloration, excessive wear and pitting. Replace crankshaft if wear

or pitting is found.

3.

Check all journal surfaces (Figure 2, Items 7 and 4) for scoring and discoloration. Replace crankshaft if

scoring or discoloration is found.

NOTE

If scoring, grooving or excessive wear exists, this may cause leakage.The seal contact

surface may be sleeved and an oversize seal may be installed.

4.

Check oil seal contact surface (Figure 2, Item 3) for scoring, grooving or excessive wear.

NOTE

Measurements of the crankshaft should be accurate to the nearest 0.0002 in.

(0.00051 cm).

5.

Measure crankshaft thrust washer surfaces (Figure 2, Item 2) for excessive wear or grooving. Replace

crankshaft if out of tolerance.

Figure 2. Crankshaft and Thrust Washer Surface Dimensions.