TM 55-2815-574-24

0069

INSPECT

1.

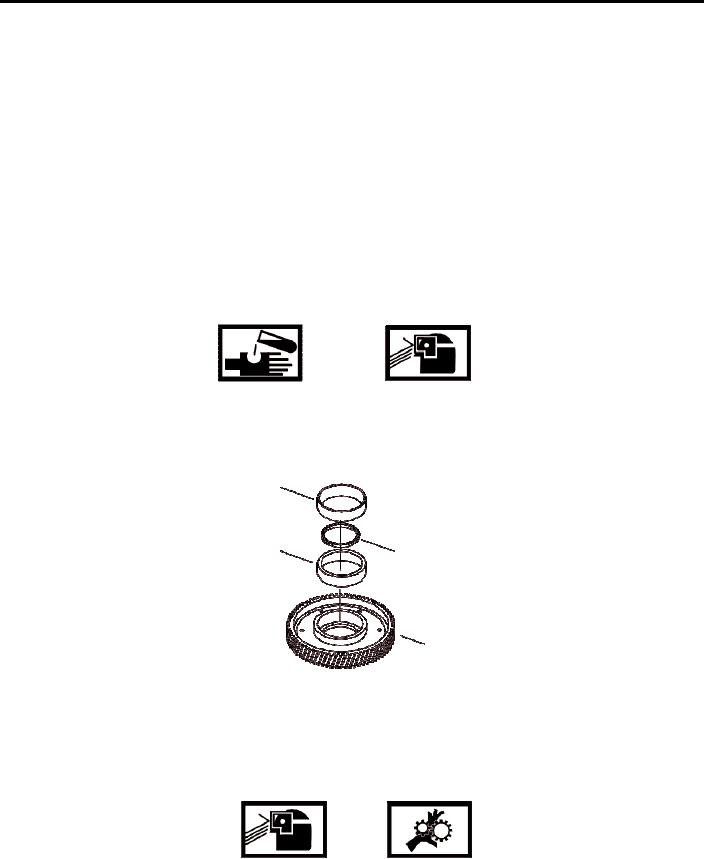

Inspect idler gear (4) for corrosion, pitting or cracking. Replace defective part.

2.

Inspect idler hub (5) for corrosion, pitting, cracking and brinelling. Replace defective part.

3.

Inspect bearings (6) for corrosion, pitting, cracking and brinelling. Replace defective part.

4.

Inspect spacer rings (7, 9) for corrosion, pitting or cracking. Replace defective part.

5.

Inspect bearing cups (8) for corrosion, pitting, cracking and brinelling. Replace defective part.

END OF TASK

ASSEMBLE

WARNING

Fuel/Oil may cause irritation to eyes or skin. Wear protective goggles, gloves, and clothing.

Failure to comply may result in personnel injury or death.

1.

Lubricate inner surface of idler gear (4) with lubricating oil.

8

8

9

4

2.

Support idler gear (4), shoulder side down, on the bed of the arbor press.

3.

Lubricate both bearing cups (8) with lubricating oil.

WARNING

Keep hands, fingers and clothing away from idler gear moving parts. Wear

protective goggles. Failure to comply may result in personnel injury.

4.

Position one of the bearing cups (8), number side up, on the idler gear (4).

5.

Using an arbor press, install the bearing cup (8) into the idler gear (4).

6.

Install spacer ring (9) on face of bearing cup (8).

0069-4