28.333.1

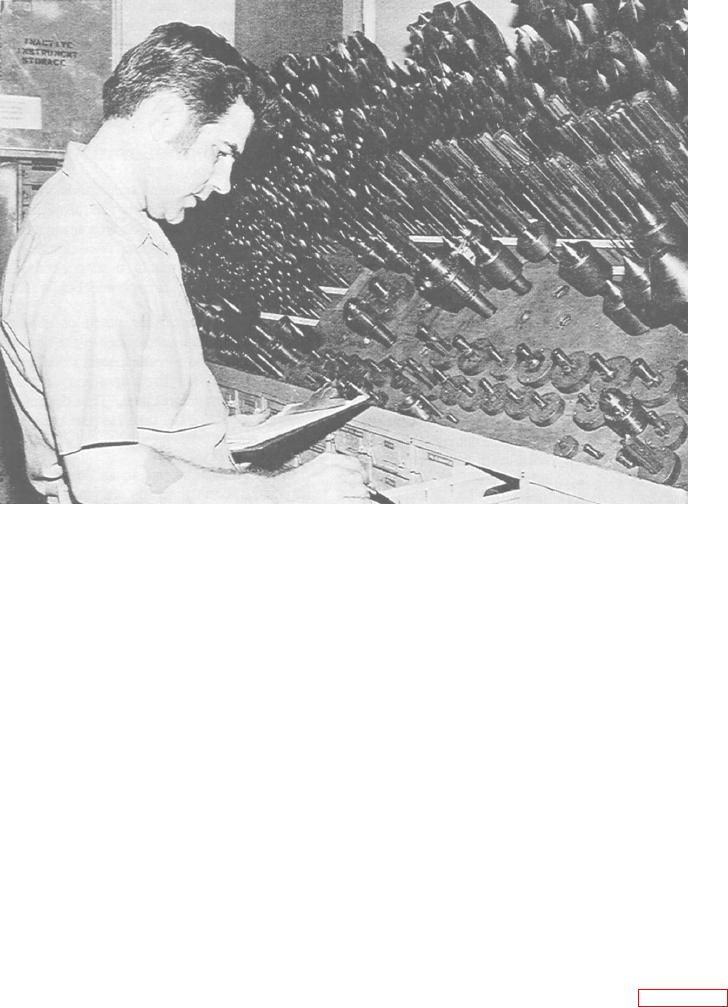

Figure 1-1.--Method of tool storage.

system. Some of the basic considerations are (1) the

Hammers, wrenches, and other tools that do not

issue and custody of tools; (2) replacement of broken,

have cutting edges are normally stored in bins. They

worn, or lost tools; and (3) proper storage and

also may be segregated by size or other designation.

maintenance of tools.

Tools with cutting edges require more space to

prevent damage to the cutting edges. These tools are

Shipboard toolrooms are limited in size by the

stored on shelves lined with wood or felt, on

design of the ship. Therefore, the space must be used

pegboards, or on hanging racks. Pegboards are

as efficiently as possible. Since the number of tools

especially adaptable for tools such as milling cutters.

required aboard ship is extensive, toolrooms usually

tend to be overcrowded. Certain peculiarities in

Make provisions to keep these tools from falling off

shipboard toolrooms also require consideration. For

the boards when the ship is rolling. Store precision

example, the motion of the ship at sea requires that

tools (micrometers, dial indicators, and so forth) in

tools be made secure to prevent movement. The

felt-lined wooden boxes in a cabinet to reduce the

moisture in the air requires that the tools be protected

effects of vibration. This arrangement allows a quick

from corrosion.

daily inventory. It also prevents the instruments from

being damaged by contact with other tools. Use

It's difficult to change permanent bins, shelves, and

rotating bins to store large supplies of small parts,

drawers in the toolroom. However, you can reorganize

such as nuts and bolts. Rotating bins provide rapid

existing storage spaces by dividing larger bins and

relocating tools to provide better use of space.

selection from a wide range of sizes. Figures 1-1,

1-3