accurate. Keep all spaces clean and free of dust to

tool storage.

prevent foreign matter from getting into the working

parts of tools. Plan to spend a portion of each day

Place frequently used tools near the issuing door

reconditioning damaged tools. This keeps the tools

so they are readily available. Place seldom used tools

available for issue and prevents an accumulation of

in out of the way areas such as on top of bins or in

damaged tools.

spaces that cannot be used efficiently because of size

and shape. Place heavy tools in spaces or areas where

a minimum of lifting is required.

CONTROL OF TOOLS

Mark all storage areas such as bins, drawers, and

There are two common methods of tool issue

lockers clearly to help locate tools. Make these

control: the tool check system and the mimeographed

markings permanent- either stencil them with paint

form or tool chit system. Some toolrooms may use a

or mark them with stamped metal tags.

combination of these systems. For example, you may

use tool checks for machine shop personnel, and

mimeographed forms for personnel outside the shop.

TOOL INSPECTION

Tool checks are either metal or plastic disks

If you are the toolroom keeper, you'll be

stamped with numbers that identify the borrower. In

responsible for the condition of all the tools and

this system the borrower presents a check for each

equipment in the toolroom. This is a very important

tool, and the disk is placed on a peg near the space

job. Inspect all tools as they are returned to determine

from which the tool was taken. The advantage of this

if they need repairs or adjustment. NEVER issue

system is that very little time is spent completing the

damaged tools since they may harm shop equipment

process.

or personnel. Set aside a space for damaged tools to

prevent issue of these tools until they have been

If the tools are loaned to all departments in the

repaired. Send any dull cutting tools to the grind shop

ship, printed forms generally are used. The form has

for regrinding. Properly dispose of any cutting tools

a space to list the tools, the borrower's name, the

that can't be reground.

division or department, and the date. This system

allows anyone in the ship's crew to borrow tools, and

Wipe clean all returned tools and give their metal

surfaces a light coat of oil. Check all precision tools

it keeps the toolroom keeper informed as to who has

upon issue and return to determine if they are

the tools and how long they have been out.

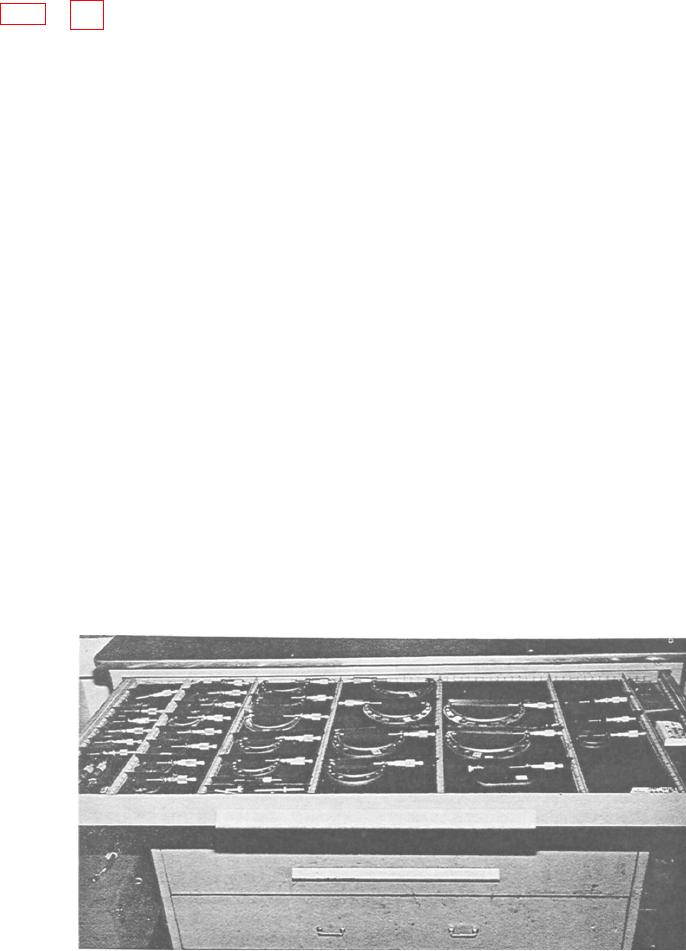

28.334

Figure 1-2.--Method of tool storage.

1-4