The correct way to measure an inside diameter is

to hold the micrometer in place with one hand as you

feel for the maximum possible setting of the

micrometer by rocking the extension rod from left to

right and in and out of the hole. Adjust the micrometer

to a slightly larger measurement after each series of

rocking movements until you can no longer rock the

rod from left to right. At that point, you should feel a

very slight drag on the in and out movement. There

are no specific guidelines on the number of positions

within a hole that should be measured. If you are

checking for taper, take measurements as far apart as

possible within the hole. If you are checking for

roundness or concentricity of a hole, take several

measurements at different angular positions in the

same area of the hole. You may take the reading

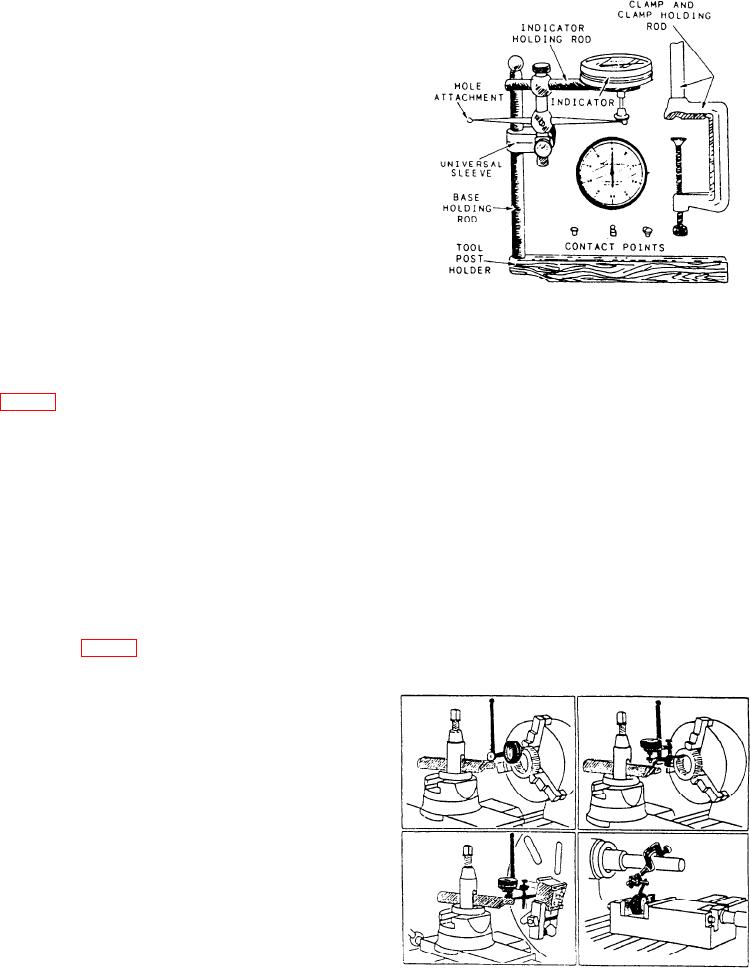

Figure 1-6.--Universal dial indicator.

directly from the inside micrometer head, or you may

use an outside micrometer to measure the inside

BLADE MICROMETER.--A blade micrometer

micrometer.

(not shown) has an anvil and a spindle that are thin

DEPTH MICROMETER.--A depth micrometer

and flat. The spindle does not rotate. This micrometer

(fig. 1-4) is used to measure the depth of holes, slots,

is especially useful in measuring the depth of narrow

counterbores, and recesses, and the distance from a

grooves, such as an O-ring seat on an outside

surface to some recessed part. This type of

diameter.

micrometer is read exactly opposite from the method

used to read an outside micrometer. The zero is

GROOVE MICROMETER.--A groove microm-

located toward the closed end of the thimble. The

eter (not shown) looks like an inside micrometer with

measurement is read in reverse and increases in

two flat disks. The distance between the disks

amount (depth) as the thimble moves toward the base

increases as you turn the micrometer. It is used to

of the instrument. The extension rods come either

measure the width of grooves or recesses on either the

round or flat (blade-like) to permit measuring a

outside or the inside diameter. The width of an

narrow, deep recess or grooves.

internal O-ring groove is an excellent example of a

THREAD MICROMETER.--The

thread

groove micrometer measurement.

micrometer (fig. 1-4) is used to measure the depth of

threads that have an included angle of 60. The

measurement obtained represents the pitch diameter

of the thread. They are available in sizes that measure

pitch diameters up to 2 inches. Each micrometer has

a given range of number of threads per inch that can

be measured correctly. You'll find additional

information on this micrometer in chapter 6.

BALL MICROMETER.--This type of microm-

eter (not shown) has a rounded anvil and a flat

spindle. It`s used to check the wall thickness of

cylinders, sleeves, rings, and other parts that have a

hole bored in a piece of material. The rounded anvil

is placed inside the hole and the spindle is brought

into contact with the outside diameter. Ball

attachments that fit over the anvil of regular outside

micrometers are also available. When using the

attachments, you must compensate for the diameter of

Figure 1-7.--Applications of a dial indicator.

the ball as you read the micrometer.

1-8