You must know the location of tools and

equipment out on loan, how long tools have been out,

and the amount of equipment and consumable

supplies you have on hand. To know this, you'll have

to make periodic inventories. The inventory consists

of a count of all tools, by type, in the toolroom and

those out on loan. Inventories help you decide

whether more strict control of equipment is needed

and if you need to procure more tools and equipment.

Some selected items, called controlled equipage,

will require an increased level of management and

control due to their high cost, vulnerability to

pilferage, or importance to the ship's mission. The

number of tools and instruments in this category is

generally small. However, it is important that you be

aware of controlled equipage items. You can get

detailed information about the designation of

controlled equipage from the supply department of

your activity. When these tools are received from the

supply department, your department head will be

required to sign a custody card for each item,

indicating a definite responsibility for management of

the item. The department head will then require

signed custody cards from personnel assigned to the

division or shop where the item will be stored and

used. As a toolroom keeper, you may control the

issue of these tools and ensure their good condition.

If these special tools are lost or broken beyond repair,

you cannot replace them until the correct survey

procedures have been completed. Conduct formal

inventories of these items periodically as directed by

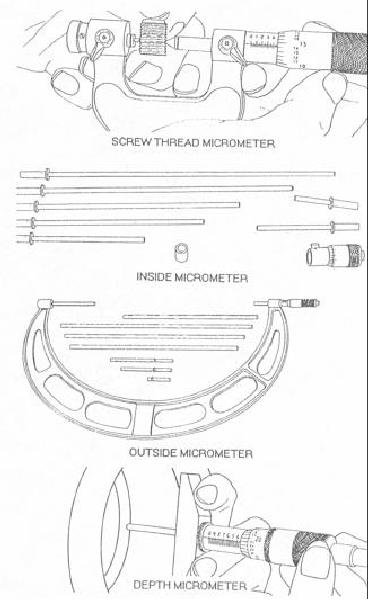

Figure 1-4.--Common types of micrometers.

your division officer or department head.

both used to compare the size or shape of an object

MEASURING INSTRUMENTS

against a scale or fixed dimension. However, there is

Practically all shop jobs require measuring or

a distinction between measuring and gauging that is

gauging. You will most likely measure or gauge flat

easily explained by an example. Suppose you are

or round stock; the outside diameters of rods, shafts,

turning work on a lathe and want to know the

or bolts; slots, grooves, and other openings; thread

diameter of the work. Take a micrometer, or perhaps

pitch and angle; spaces between surfaces; or angles

an outside caliper, adjust its opening to the exact

and circles.

diameter of the workpiece, and determine that

For some of these operations, you'll have a choice

dimension numerically. On the other hand, if you

of which instrument to use, but in other instances

want to turn a piece of work down to a certain size

you'll need a specific instrument. For example, when

without frequently taking time to measure it, set the

precision is not important, a simple rule or tape will

caliper at a reading slightly greater than the final

be suitable. In other instances, when precision is

dimension; then, at intervals during turning

important, you'll need a micrometer.

operations, gauge, or "size," the workpiece with the

locked instrument. After you have reduced the

The term gauge, as used in this chapter identifies

workpiece dimension to the dimension set on the

any device that can be used to determine the size or

instrument, you will, of course, need to measure the

shape of an object. There is no significant difference

work as you finish it to the exact dimension.

between gauges and measuring instruments. They are

1-6