get the points for the number 4 elements in the

circumference of the upper section of the T, or equal to

stretchout.

twice the distance that you stepped off in the half-plan.

The height of the stretchout, obtained by projection, is

14. Through each of the points located, draw the

equal to the maximum height of the T. The height is

element lines parallel to line 1.

equal to the length of the longest element in the side

15. Project the elements of the side elevation view

elevation--in figure 12-46, element number 4.

to the correspondingly numbered elements in the

9. Step off, locate, and number the element lines

stretchout. Connect the intersecting points with curved

in the stretchout.

lines to outline the hole.

10. Project the points of intersection locating the

16. Add seams to the stretchout as required.

miter in the side elevation. Draw the curve through these

Remember, the amount you will allow for seams will

points.

depend upon the method you plan to use for joining.

11. Now, using the circumference and length of the

When the layout is completed, transferred to sheet

main pipe for dimensions, draw the stretchout for the

metal, and formed, you should have a shape that looks

like the one shown in figure 12-48.

main pipe as shown in figure 12-47.

You have been shown how to develop patterns for

12. Bisect the length of the stretchout with an

a drip pan or box by the straight line angular method of

element line, and number that line 1.

development, and methods for making stretchouts for

13. Set your dividers for the distance from 1 to 2

elbows, pipe intersection angles, and T-joints by the

in the half-plan in the elevation. Using this radius and

parallel line method. Each of these methods has many

the point at which line 1 intersects the right-hand edge

more applications and you will use them often.

of the stretchout, scribe an arc on either side of 1 on the

However, you would not be able to develop some of the

edge of the stretchout. Number each of these points 2.

patterns that you will run into without a working

Now, setting the dividers for the distance from 1 to 3 in

knowledge of the method for radial line pattern

the half-plan of the elevation, scribe arcs, using 1 as a

development.

center, on either side of element 1 in the stretchout.

Number both of these points 3. Repeat the procedure to

RADIAL LINE METHOD

The radial line method of pattern development uses

some of the features of parallel line development. You

will recognize them when you lay out a frustum of a

right cone. You are familiar with the shape of a cone. A

right cone is one that would stand straight, up and down,

when resting on its large end. In other words, a center

line drawn from the point, or vertex, to the base line,

would form right angles with that line. The frustum of

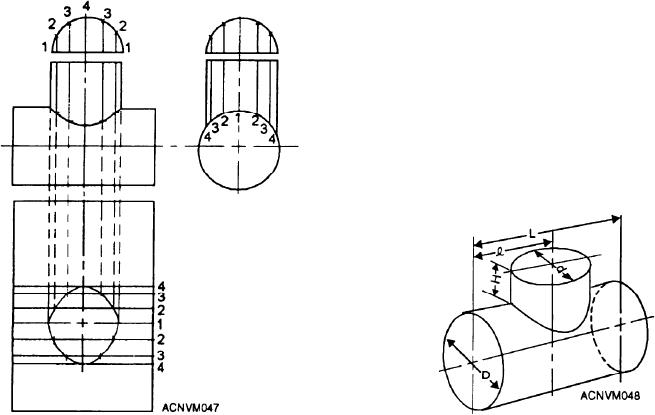

Figure 12-48.--Pictorial view of a T-joint.

Figure 12-47.--Stretchout of the main pipe in the T-joint.

12-18