TM 55-2815-574-24

0056

CLEANING - Continued

5.

Clean inside diameter of valve guides, using valve guide brush, to remove gum and/or carbon deposits.

END OF TASK

INSPECTION

1.

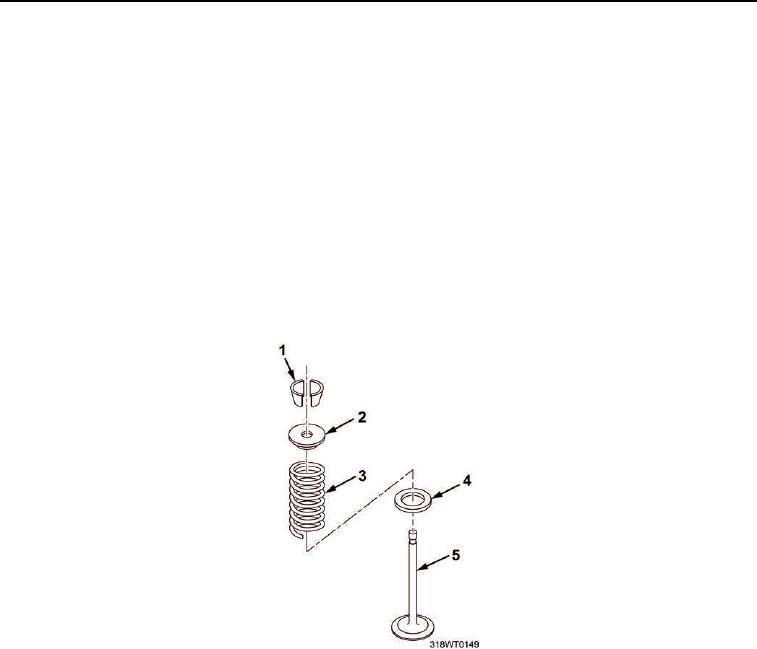

Inspect valve lock (Figure 1, Item 1) for cracks or fractures.

2.

Inspect spring cap (Figure 1, Item 2) for cracks and wear.

3.

Inspect spring (Figure 1, Item 3) for pitting or fractures.

4.

Using outside micrometer, verify outside diameter of spring (Figure 1, Item 3) is 0.9531 in. (2.42 cm).

5.

Using spring tester, compress spring (Figure 1, Item 3) to 1.80 in. (4.572 cm).

6.

Verify minimum of 25 lb (11.35 kg) required to compress valve spring (Figure 1, Item 3).

Figure 1. Exhaust Valve Components.

7.

Inspect exhaust valve (Figure 2, Item 1) seat for cracks and wear. Replace defective parts.

8.

Using machinists rule, check the thickness of valve (Figure 2, Item 1) edge. Thickness should be

0.031 in. (0.0787 cm).

9.

Using outside micrometer, check the diameter of the valve stem (Figure 1, Item 5). Diameter should be

0.3100 to 0.3108 in. (0.7874 to 0.7894 cm). Repair or replace damaged parts.

10.

Using machinist ruler, check the width of the valve face (Figure 2, Item 1). Width should be

0.046 to 0.093 in. (0.1168 to 0.2362 cm). Repair or replace damaged parts.

11.

Inspect valve (Figure 2, Item 1) face head for warping.

12.

Inspect valve (Figure 2, Item 1) face stem for scuff marks, scratches, and wear.

13.

Inspect valve (Figure 2, Item 1) face for ridges, cracks, and pitting. Repair or replace damaged part.