TM 55-2815-574-24

0111

ASSEMBLE - Continued

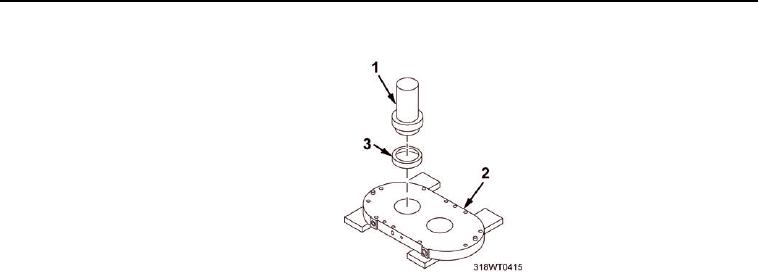

Figure 10.

a.

Support the end plate (Figure 7, Item 2 and Figure 7, Item 3) on wooden blocks with the finished side

facing up on the arbor press.

b.

Start the new oil seal (Figure 7, Item 5) straight into the bore of the end plate (Figure 7, Item 2 and

Figure 7, Item 3) with the sealing edge of the seal facing down.

c.

Place the short end of oil seal remover/installer J 6270-3 (35) onto oil seal (Figure 7, Item 5).

NOTE

A step under the shoulder of the installer will position the oil seal approximately 0.005 in.

below the finished face of the end plate. This will be within the 0.002 - 0.008 in. tolerances

specified.

d.

Lower the ram of the press until the shoulder of the installer contacts end plate (Figure 7, Item 2 and

Figure 7, Item 3).

e.

Install the remaining oil seals (Figure 7, Item 5) in end plates (Figure 7, Item 2 and

Figure 7, Item 3) using the same steps.

NOTE

If the seal surface on the Rotor shaft was worn, an oversize seal and sleeve will need to be

used. If standard size seals are to be used, skip Step 2.

2.

Install the oversize seal (Figure 10, Item 3) and sleeve (Figure 11, Item 2).