TM 55-2815-574-24

0052

INSPECTION - Continued

5.

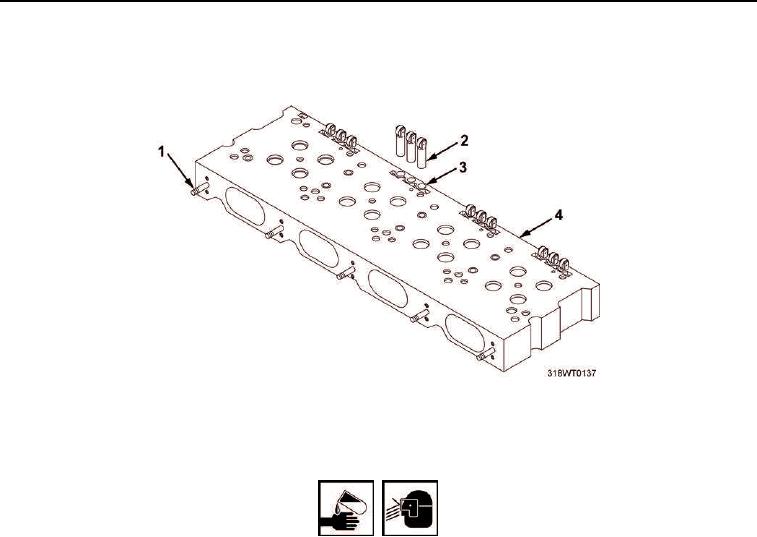

Inspect cam follower bores (Figure 4, Item 3) for scoring or wear.

Figure 4. Cam Follower Bore Inspection.

WARNING

Cleaning compound may cause irritation to the eyes or skin. Use in well-ventilated areas.

Wear protective goggles and clothing. In case cleaning compound comes in contact with:

Eyes, flush immediately with water.

Skin, wash with soap and water.

Failure to comply may result in personnel injury.

6.

Use abrasive cloth wet with cleaning compound to remove light scoring. Discard cylinder head

(Figure 3, Item 4) with scoring that cannot be removed.

7.

Measure and record cam follower bore (Figure 4, Item 3) diameters using inside micrometer. Measurement

should be between 1.0620 to 1.0630 in. (2.6924 to 2.6949 cm).

8.

Measure and record diameter of cam followers (Figure 4, Item 2) using outside micrometer. Measurement

should be between 1.0600 to 1.0610 in. (2.6975 to 2.7000 cm).

9.

Verify that clearance between cam follower(s) and cam follower bore(s) (Figure 4, Item 3) does not exceed

0.002 in. (0.00508 cm). Discard defective part.

NOTE

The cam follower bore to cam follower clearance for used cylinder head and used cam

follower must not exceed 0.006 in. (0.01524 cm).

10.

Inspect exhaust manifold studs (Figure 4, Item 1) for stripped threads, bending or cracks. Replace damaged

studs.

END OF TASK